Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Exploring the Energy-Saving Advantages of Installation Automatic Pump Control Systems

Wholesale Installation Automatic Pump Control Manufacturer

In the contemporary industrial landscape, where sustainability and energy efficiency are paramount, the Installation Automatic Pump Control systems has emerged as a beacon of innovation. These systems are designed to optimize the performance of pumps, thereby reducing energy consumption and operational costs. The Installation Automatic Pump Control systems offers a plethora of advantages in terms of energy savings, which this article will delve into, highlighting the mechanisms and benefits that make them indispensable in modern facilities.

One of the primary ways in which the Installation Automatic Pump Control systems contributes to energy conservation is through their variable speed drive (VSD) technology. By adjusting the speed of the pump in real-time according to the system's demand, the Installation Automatic Pump Control system ensures that the pump operates at an efficient speed, thus reducing energy wastage. This is in stark contrast to traditional pump systems that operate at a constant speed, regardless of the demand, causing significant energy losses.

Another significant advantage of installing automatic Pump Control systems is their ability to prevent system overload. By closely monitoring the pressure, flow, and other operational parameters, these systems can detect and prevent overload conditions before they occur. This prevents the pump from working harder than necessary, which not only saves energy but also extends the pump's lifespan by reducing wear and tear.

The integration of smart sensors and advanced algorithms within the Installation Automatic Pump Control systems allows for precise control over the pump's operation. These systems can predict and adapt to changes in demand, ensuring that the pump operates at a suitable level at all times. This predictive control mechanism reduces energy consumption by avoiding unnecessary fluctuations in the pump's operation.

Installation Automatic Pump Control systems also plays a crucial role in leak detection and prevention. By monitoring the system continuously, they can identify small changes in pressure or flow that may indicate a leak. Prompt detection and resolution of leaks not only prevent water wastage but also reduce the energy required to pump the same volume of liquid, as leaks can create additional resistance.

Furthermore, the Installation Automatic Pump Control systems facilitates the implementation of energy-efficient pumps. By providing real-time data on pump performance, these systems help operators select energy-efficient pumps for their specific application. This selection process is based on accurate data rather than guesswork, causing more informed decisions that contribute to energy savings.

The Installation Automatic Pump Control systems also contributes to energy savings by reducing the need for manual intervention. By automating the control processes, these systems reduce the likelihood of human error, which can cause inefficient operation. Automation ensures that the pump operates within the desired parameters at all times, without the need for constant monitoring by personnel.

In addition to the direct energy savings, the Installation Automatic Pump Control systems also contributes to indirect savings by improving the overall efficiency of the facility. By ensuring that the pumps operate at good efficiency, these systems reduce the need for additional equipment, such as booster pumps, which can consume significant energy.

Lastly, the Installation Automatic Pump Control systems provides valuable data that can be used for energy management and optimization. By analyzing the data collected by these systems, operators can identify trends and patterns that can inform decisions on system upgrades, maintenance schedules, and operational strategies, all of which can cause further energy savings.

In conclusion, the Installation Automatic Pump Control systems offers a multitude of advantages in terms of energy conservation. Their ability to optimize pump operation, prevent overload, detect leaks, and facilitate energy-efficient decision-making make them a vital component in the pursuit of sustainable and efficient industrial operations. As the push towards greener technologies continues, the role of the Installation Automatic Pump Control systems in energy savings will only become more significant, ensuring their place as a cornerstone in the future of industrial automation.

-

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

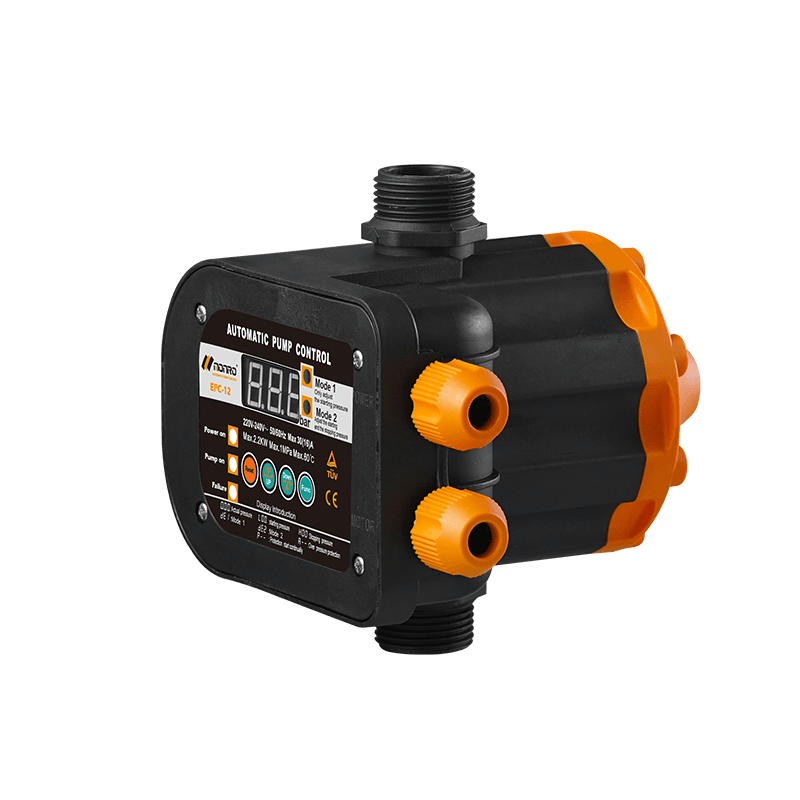

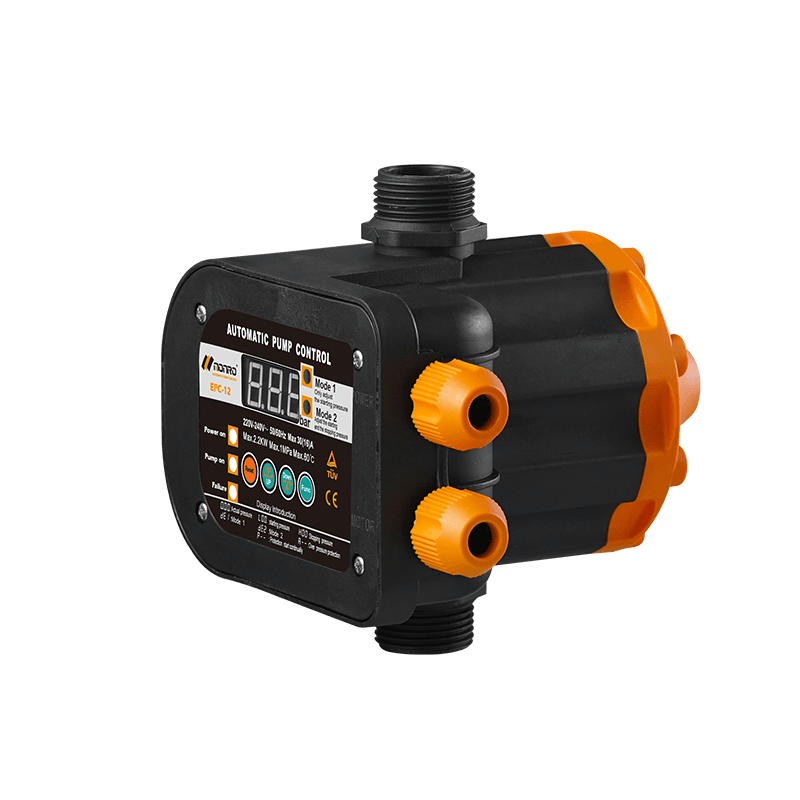

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español