Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Ensuring Stability and Reliability in Installation Automatic Pump Control Systems

Sale Installation Automatic Pump Control Maker in China

The Installation Automatic Pump Control systems is integral to various industries, from water treatment to chemical processing. Their primary function is to regulate the flow of liquids, ensuring efficient operation and safety. To guarantee the stability and reliability of these systems, a multi-faceted approach must be adopted, encompassing design, installation, operation, and maintenance. This article will explore the critical factors that contribute to the successful implementation and ongoing performance of Installation Automatic Pump Control systems.

The design phase of Installation Automatic Pump Control systems is crucial. Engineers must select components that are not only technologically advanced but also robust enough to withstand the specific conditions of the application. The use of high-quality materials and precision engineering ensures that the Installation Automatic Pump Control systems can endure the rigors of continuous operation without failure. Additionally, the integration of fail-safe mechanisms and redundant systems can provide an extra layer of protection against unexpected malfunctions.

During the installation process, adhering to manufacturer guidelines and industry standards is paramount. The Installation Automatic Pump Control systems must be correctly positioned to facilitate easy access for maintenance and to ensure suitable performance. Installers must also pay close attention to the connections and wiring, as improper installation can cause leaks, electrical faults, or even system failure.

Once the Installation Automatic Pump Control systems are installed, regular operation and monitoring are essential for maintaining stability and reliability. Operators should be trained to recognize signs of wear or malfunction, such as unusual noises, vibrations, or changes in performance. Implementing a routine check-up schedule can help catch minor issues before they escalate into major problems. Furthermore, the use of advanced diagnostic tools and software can provide real-time data on the system's performance, allowing for proactive maintenance and adjustments.

Maintenance is a critical component of ensuring the longevity and reliability of Installation Automatic Pump Control systems. Regular servicing, which includes cleaning, lubrication, and replacement of worn parts, can significantly extend the life of the pumps and associated components. It is also essential to keep abreast of any software updates or firmware patches that may enhance the system's performance or fix known issues.

Environmental factors also play a significant role in the stability and reliability of Installation Automatic Pump Control systems. Ensuring that the systems are protected from bad temperatures, humidity, and other environmental conditions can help prevent corrosion and other forms of damage. Additionally, protecting the systems from potential physical damage, such as impacts or vandalism, can also contribute to their overall reliability.

In conclusion, the stability and reliability of Installation Automatic Pump Control systems are dependent on a combination of careful design, meticulous installation, vigilant operation, and consistent maintenance. By addressing each of these areas, industry professionals can ensure that their Installation Automatic Pump Control systems performs, providing a reliable and efficient means of liquid regulation. As the reliance on these systems grows, so too must the commitment to their ongoing care and optimization, ensuring that the Installation Automatic Pump Control systems remains a cornerstone of industrial fluid management.

-

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

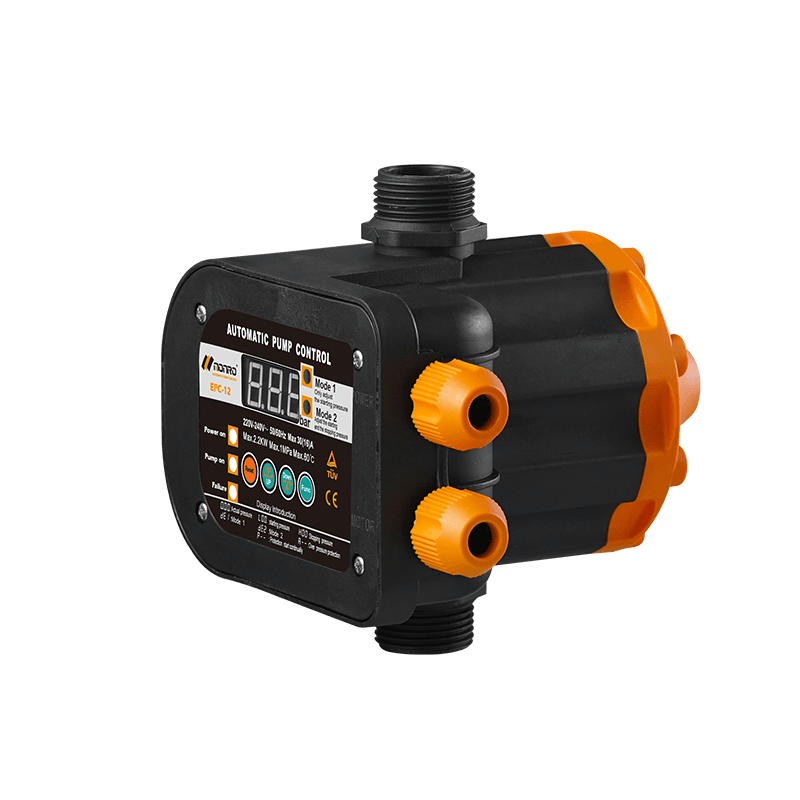

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español