Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Analysis of Energy Consumption in the Installation Automatic Pump Control Systems

High Quality Installation Automatic Pump Control Producer

The Installation Automatic Pump Control systems is at the forefront of technological advancements in fluid management, offering a range of benefits that extend beyond mere operational efficiency. A critical aspect of these systems is their impact on energy consumption, a factor that is increasingly important in the context of global sustainability goals. This article will provide an in-depth analysis of the energy consumption characteristics of Installation Automatic Pump Control systems, examining their design, operation, and the strategies employed to decrease energy usage.

The fundamental principle behind the energy efficiency of Installation Automatic Pump Control systems lies in their ability to precisely control the operation of pumps based on real-time demand. Traditional pump systems often operate at a fixed speed, which can cause excessive energy consumption when the demand for fluid flow is lower than the system's capacity. Installation Automatic Pump Control systems, on the other hand, adjust the pump speed to match the exact requirements of the process, thereby reducing unnecessary energy expenditure. This variable speed control is a key feature that contributes to the reduced energy consumption of Installation Automatic Pump Control systems.

Another aspect of the Installation Automatic Pump Control systems that impact energy consumption is their integration with advanced sensors and monitoring devices. These components allow for continuous monitoring of fluid levels, pressures, and flow rates, providing the necessary data for the Installation Automatic Pump Control system to make informed decisions about pump operation. By leveraging this information, the Installation Automatic Pump Control systems can optimize pump performance, avoiding scenarios where pumps operate at partial capacity or against closed valves, both of which can cause significant energy waste.

The energy consumption of Installation Automatic Pump Control systems is also influenced by their control algorithms. Sophisticated algorithms can predict demand patterns and adjust pump operations proactively, further reducing energy use. For instance, an Installation Automatic Pump Control system might anticipate a spike in demand and gradually increase pump speed, avoiding the energy-intensive process of rapidly ramping up from a standstill.

Maintenance and upkeep play a crucial role in the ongoing energy efficiency of the Installation Automatic Pump Control systems. Regular maintenance ensures that pumps and control systems are operating at good performance, reducing friction and wear that can increase energy consumption over time. Additionally, updating the Installation Automatic Pump Control systems with software can introduce new energy-saving features and improvements.

The environmental benefits of reduced energy consumption in the Installation Automatic Pump Control systems cannot be overstated. Lower energy usage directly translates to reduced greenhouse gas emissions, contributing to the global effort to combat climate change. Moreover, the economic benefits are significant, as reduced energy consumption causes lower operational costs for industries that rely on fluid management.

In conclusion, the energy consumption of Installation Automatic Pump Control systems is a multifaceted issue that encompasses design, operation, and maintenance. By employing variable speed control, advanced monitoring, intelligent algorithms, and regular maintenance, Installation Automatic Pump Control systems can significantly reduce energy consumption, providing both economic and environmental benefits. As industries increasingly seek to improve their energy efficiency and sustainability, the role of installing automatic Pump Control systems becomes more critical, and understanding their impact on energy consumption is essential for making informed decisions about their implementation and optimization.

-

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

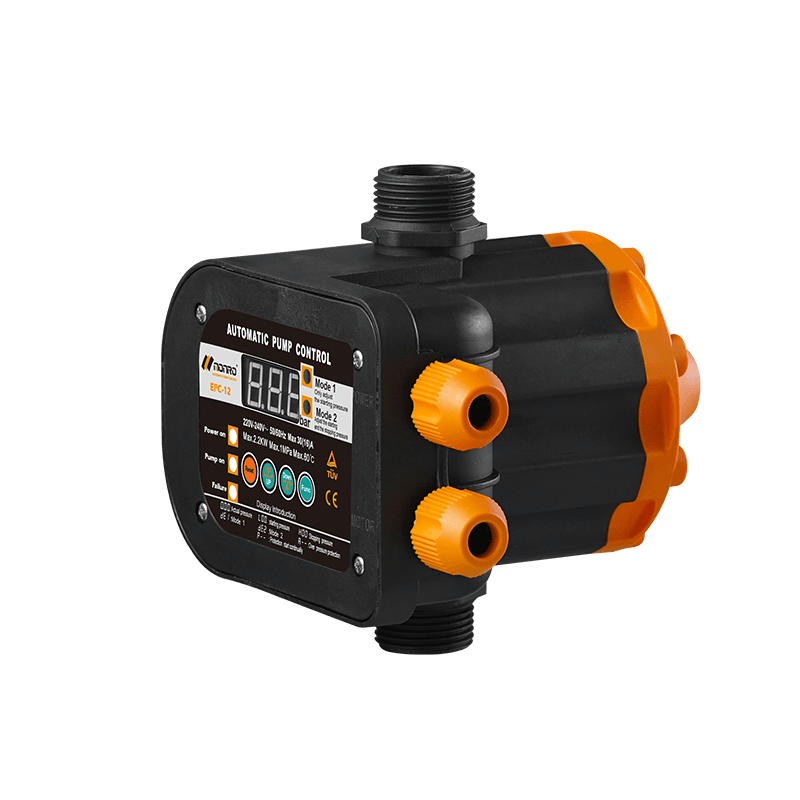

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español