Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Evaluating the Performance Variability of Installation Automatic Pump Control Across Temperature Ranges

Design Custom Installation Automatic Pump Control Factory

The performance of the Installation Automatic Pump Control systems is a critical factor in ensuring the reliability and efficiency of fluid management processes. These systems are designed to operate under a variety of conditions, and their ability to maintain suitable performance across different temperature ranges is a significant concern for industries worldwide. This comprehensive exploration will delve into how Installation Automatic Pump Control systems perform in varying thermal environments, assessing their adaptability and potential limitations.

The operation of Installation Automatic Pump Control systems is inherently linked to the temperature of the fluid they manage. High temperatures can cause the viscosity of the fluid to decrease, which may affect the pump's efficiency and the control system's ability to maintain a consistent flow rate. Conversely, low temperatures can increase fluid viscosity, potentially causing higher energy consumption as the pump struggles to move the thicker fluid. Understanding these dynamics is crucial for the effective operation of Installation Automatic Pump Control systems in diverse industrial settings.

In high-temperature environments, the primary concern for the Installation Automatic Pump Control systems is the potential for damage to the pump components and the control mechanisms. The heat can cause materials to expand, which may cause misalignment and increased wear and tear on the pump. Additionally, the electronic components within the Installation Automatic Pump Control system may be susceptible to damage from prolonged exposure to high temperatures, which can compromise the system's reliability. To counteract these issues, Installation Automatic Pump Control systems are often designed with heat-resistant materials and cooling mechanisms to ensure stable operation.

On the other hand, low-temperature conditions present a different set of challenges for Installation Automatic Pump Control systems. As mentioned earlier, the increased viscosity of the fluid at lower temperatures can place additional stress on the pump, causing higher energy consumption and potential mechanical stress. Moreover, the cold can cause certain materials to become brittle, which may result in component failure. To mitigate these risks, the Installation Automatic Pump Control systems must incorporate materials that are resistant to temperature extremes and may employ heating elements to maintain fluid and component temperatures within safe operating ranges.

Another consideration for the Installation Automatic Pump Control systems in varying temperatures is the control algorithms themselves. These algorithms must be capable of adjusting to the changing conditions to maintain suitable performance. In high-temperature scenarios, the Installation Automatic Pump Control system may need to increase the frequency of control adjustments to compensate for the rapid changes in fluid properties. In contrast, at low temperatures, the system may need to anticipate and adjust for the slower response times of the pump and the increased viscosity of the fluid.

The calibration and accuracy of the sensors within the Installation Automatic Pump Control system are also affected by temperature fluctuations. These sensors are crucial for monitoring flow rates, pressures, and temperatures, and any inaccuracies can cause poor control and inefficiencies. Therefore, Installation Automatic Pump Control systems must be equipped with temperature-compensated sensors that maintain their accuracy across a wide range of temperatures.

In conclusion, the performance of the Installation Automatic Pump Control systems is significantly influenced by the temperature of the operating environment. These systems must be designed with temperature resilience in mind, incorporating heat-resistant materials, adaptive control algorithms, and accurate temperature-compensated sensors. By addressing these challenges, Installation Automatic Pump Control systems can maintain their efficiency and reliability in a variety of temperature conditions, ensuring the smooth operation of fluid management processes in diverse industrial applications.

-

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

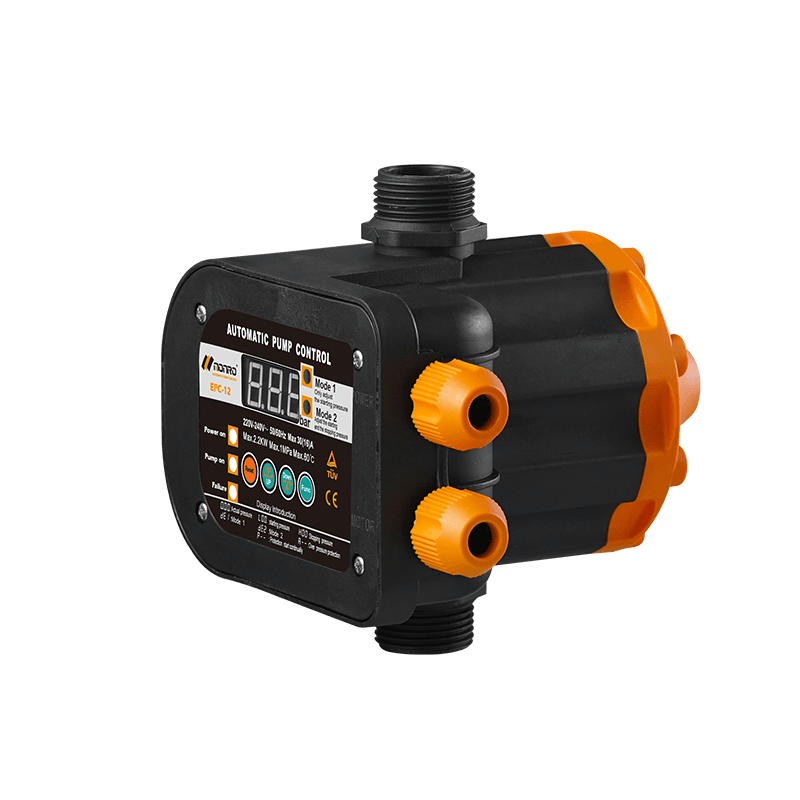

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español