Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

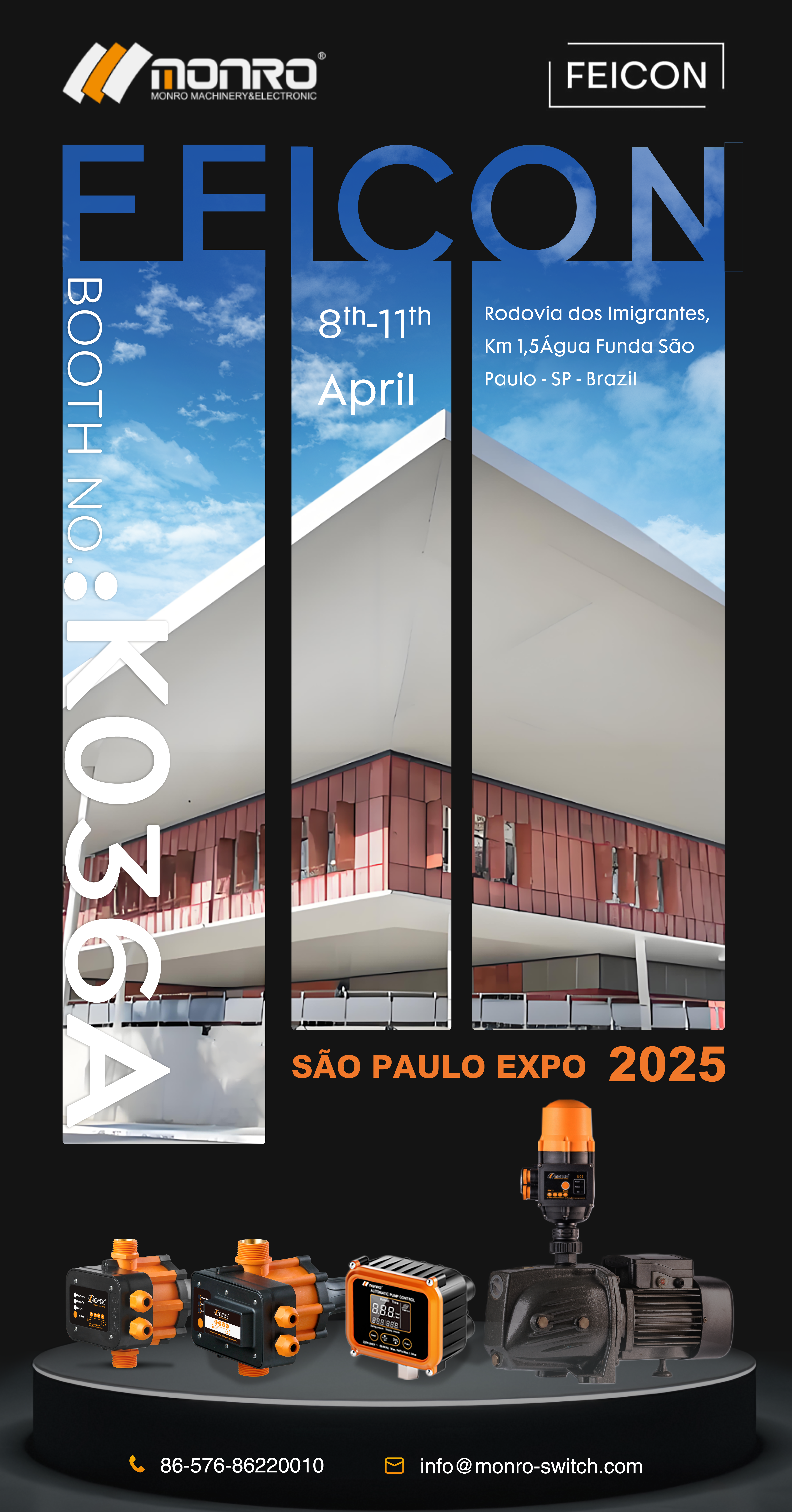

Evaluating the Performance of Automatic Pump Control Across Varied Temperature Conditions

Sale China Design Custom Automatic Pump Control Wholesaler

The performance of Automatic Pump Control (APC) systems is a critical consideration in industries where fluid management is essential. These systems are designed to maintain precise control over fluid flow and pressure, and their reliability is tested across a spectrum of environmental conditions, particularly temperature. The ability of Automatic Pump Control systems to operate efficiently in different temperature conditions is a measure of their robustness and adaptability.

In high-temperature environments, the Automatic Pump Control system faces challenges such as increased wear and tear on mechanical components, potential for thermal expansion, and the risk of overheating of electronic components. To address these issues, APC systems are often engineered with heat-resistant materials and cooling mechanisms. The software within these systems may include algorithms that adjust the pump's operation parameters to prevent overheating and maintain suitable performance. For instance, the Automatic Pump Control software might reduce the speed of the pump or alter the duty cycle to dissipate heat more effectively.

Conversely, in low-temperature conditions, the Automatic Pump Control system must contend with the risk of fluid freezing, reduced viscosity, and potential for mechanical seizing. The hardware of the APC system may incorporate heating elements or insulation to keep the fluid and components within an operational temperature range. The software, in this case, would monitor the temperature and adjust the pump's operation to prevent freezing and to ensure that the fluid remains in a state that allows for smooth operation.

The Automatic Pump Control system's performance in varying temperatures is also influenced by the materials used in its construction. High-quality materials that can withstand temperature extremes are essential for the longevity and reliability of the system. Additionally, the design of the pump and its components must take into account the thermal properties of the fluids being managed, as different fluids have different temperature sensitivities.

In some cases, the Automatic Pump Control system may be equipped with sensors that monitor the temperature of the fluid and the environment. These sensors provide real-time data to the system's software, which can then make adjustments to the pump's operation to maintain suitable conditions. For example, if the temperature drops below a certain threshold, the software might increase the flow rate to generate more frictional heat within the fluid, thereby preventing it from freezing.

The calibration of the Automatic Pump Control system is another aspect that must be considered when operating in different temperature conditions. Calibration ensures that the system's readings and responses are accurate, and it may need to be adjusted for different temperature ranges to maintain this accuracy. The software within the APC system can be programmed to recognize when calibration is necessary and to initiate the process automatically.

Maintenance is also a key factor in the performance of Automatic Pump Control systems in varying temperatures. Regular maintenance can help to identify and address potential issues before they become critical, such as checking for signs of wear, ensuring that seals and gaskets are in good condition, and verifying that the system's components are clean and free of debris. The Automatic Pump Control software can be used to track maintenance schedules and to alert operators when maintenance is due.

In conclusion, the performance of Automatic Pump Control systems in different temperature conditions is a complex interplay of hardware design, software functionality, material selection, calibration, and maintenance. By understanding and addressing these factors, industries can ensure that their APC systems operate reliably and efficiently, regardless of the temperature conditions they face. This is crucial for maintaining the integrity of processes that depend on the precise control of fluid flow and pressure, and it underscores the importance of investing in high-quality Automatic Pump Control systems that are designed to perform in a wide range of environmental conditions.

-

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

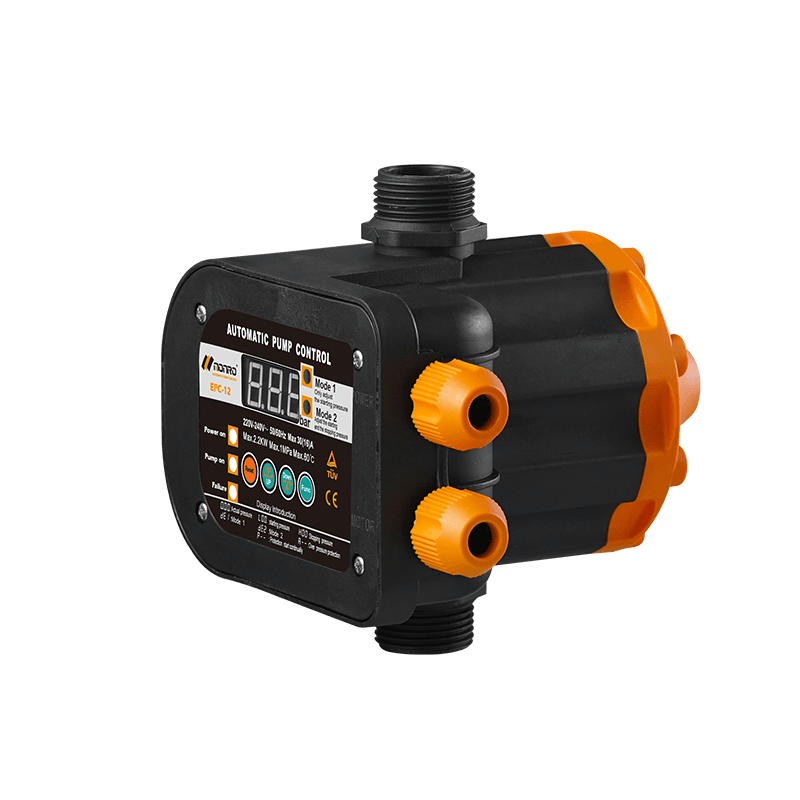

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español