Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

In-Depth Examination of the Calibration Process at Pressure Switch Factory

China Design OEM Pressure Control Switch Factory Company

The calibration process at Pressure Switch Factory is a meticulous and critical procedure that ensures the accuracy and precision of every pressure switch that leaves their facility. As a cornerstone of their quality control measures, the calibration process at Pressure Switch Factory is designed to meet and exceed industry standards, ensuring that each pressure switch performs in its intended environment. This comprehensive approach to calibration is a reflection of their dedication to manufacturing well and customer satisfaction.

At the heart of the Pressure Switch Factory's calibration process is a series of standardized tests and adjustments that are performed on each unit. These tests are carried out in a controlled environment that simulates the various conditions the pressure switches will encounter in real-world applications. The process begins with an inspection of the pressure switch's mechanical components, ensuring that there are no defects or inconsistencies that could affect performance.

One step in the calibration process at Pressure Switch Factory involves the use of precision instruments to measure the switch's response to different pressure levels. This is done to establish a baseline for the switch's performance and to identify any deviations from the expected response. The data collected during this stage is crucial for determining the necessary adjustments that will be made to the pressure switch.

Once the baseline measurements have been taken, the pressure switches are subjected to a series of calibration adjustments. These adjustments are made by skilled technicians who have been trained in the specific techniques required to fine-tune the pressure switches to meet the precise specifications set by the Pressure Switch Factory. The adjustments are made incrementally, with each change being carefully monitored and recorded to ensure that the desired level of accuracy is achieved.

Throughout the calibration process, the pressure switches are also tested for their durability and reliability. This involves subjecting the switches to a range of pressure cycles to simulate the wear and tear they will experience over time. The results of these tests are used to further refine the calibration, ensuring that the pressure switches not only meet the required accuracy but also maintain this performance over an extended period.

The calibration process at Pressure Switch Factory also includes a rigorous quality control check. Each pressure switch is inspected and tested after calibration to confirm that it meets the factory's stringent standards. Any units that do not pass these checks are either re-calibrated or set aside for further analysis, ensuring that only high-quality pressure switches are shipped to customers.

In addition to the physical calibration process, Pressure Switch Factory also employs advanced software and algorithms to further refine the calibration of their pressure switches. This software allows for the precise adjustment of the switch's electronic components, which can affect the accuracy of the pressure readings. The use of this technology is a testament to Pressure Switch Factory's commitment to leveraging advancements in technology to improve its products.

The final stage of the calibration process at Pressure Switch Factory involves the creation of a detailed calibration report for each pressure switch. This report documents the switch's performance throughout the calibration process and provides a record of the adjustments made. This level of documentation is important for both the factory and their customers, as it provides a clear record of the switch's performance and allows for any necessary future adjustments to be made with ease.

In conclusion, the calibration process at Pressure Switch Factory is a complex and multifaceted procedure that ensures high levels of accuracy and precision in their pressure switches. By combining rigorous testing, skilled technician adjustments, and advanced software technology, Pressure Switch Factory can produce pressure switches that meet the demands of even discerning customers. Their dedication to this process is a clear indicator of their commitment to well and their ongoing pursuit of manufacturing high-quality pressure switches in the industry.

-

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

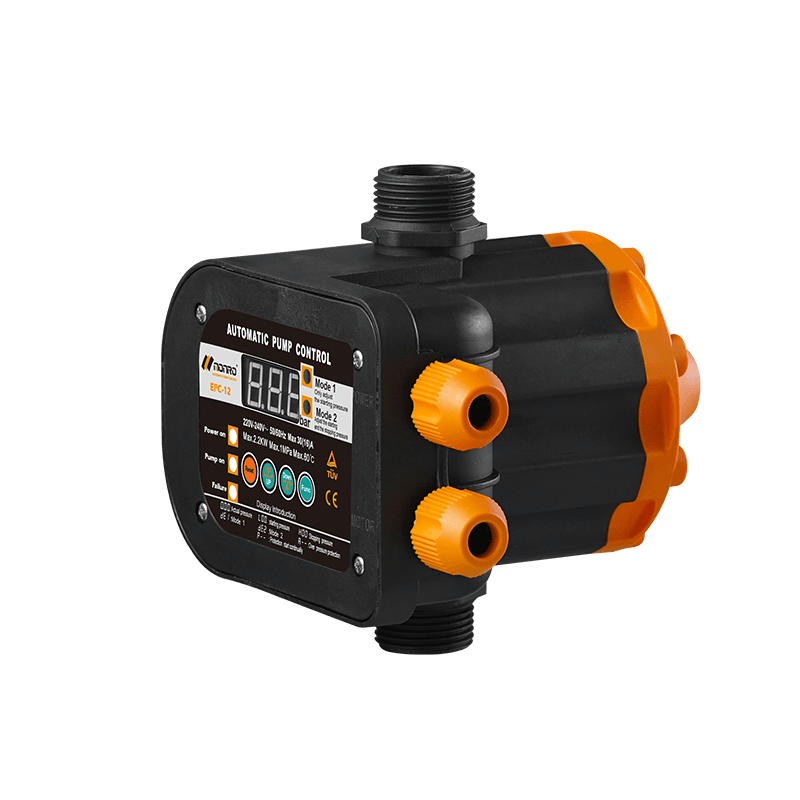

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español