Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Electric Air Pressure Switches and Electric Water Pump Switches in Modern Industrial Applications

In the modern industrial landscape, the efficient and reliable operation of machinery and systems is of paramount importance. Two critical components that play a significant role in ensuring this efficiency and reliability are electric air pressure switches and electric water pump switches. These devices are designed to monitor and control the operation of air and water systems, respectively, by turning them on or off based on specific pressure or flow conditions.

1. Electric Air Pressure Switches

An electric air pressure switch is a device that monitors the pressure of an air system and controls the operation of an air compressor or other air-related equipment. It is designed to maintain a consistent air pressure level within a specified range, ensuring the good performance of the system.

1.1 Functions of Electric Air Pressure Switches

The primary function of an electric air pressure switch is to regulate the pressure within an air system. It does this by turning the air compressor on or off based on the pressure readings it receives. When the pressure drops below a predetermined set point, the switch activates the compressor to increase the pressure. Conversely, when the pressure rises above a set upper limit, the switch deactivates the compressor to prevent over-pressurization.

1.2 Applications of Electric Air Pressure Switches

Electric air pressure switches are used in a wide range of industrial applications, including:

a. Pneumatic tools and machinery

b. Air conditioning and refrigeration systems

c. Medical equipment

d. Automotive and transportation systems

e. Industrial automation and control systems

1.3 Benefits of Electric Air Pressure Switches

The use of electric air pressure switches offers several benefits, such as:

a. Improved system efficiency: By maintaining consistent pressure levels, the switch ensures that the air system operates at its good performance.

b. Enhanced safety: Over-pressurization can lead to dangerous situations, and the switch helps prevent this by deactivating the compressor when necessary.

c. Extended equipment life: Consistent pressure levels reduce wear and tear on air compressors and other air-related equipment, professional to a longer lifespan.

d. Cost savings: Efficient operation and reduced wear and tear can result in lower energy consumption and maintenance costs.

2. Electric Water Pump Switches

An electric water pump switch is a device that monitors the water flow or pressure in a system and controls the operation of a water pump. It is designed to maintain a consistent water flow or pressure level within a specified range, ensuring the good performance of the water system.

2.1 Functions of Electric Water Pump Switches

The primary function of an electric water pump switch is to regulate the water flow or pressure within a system. It does this by turning the water pump on or off based on the flow or pressure readings it receives. When the flow or pressure drops below a predetermined set point, the switch activates the pump to increase the flow or pressure. Conversely, when the flow or pressure rises above a set upper limit, the switch deactivates the pump to prevent over-pressurization or excessive flow.

2.2 Applications of Electric Water Pump Switches

Electric water pump switches are used in a wide range of applications, including:

a. Domestic water supply systems

b. Irrigation systems

c. Industrial water treatment and processing systems

d. Heating, ventilation, and air conditioning (HVAC) systems

e. Fire protection and sprinkler systems

2.3 Benefits of Electric Water Pump Switches

The use of electric water pump switches offers several benefits, such as:

a. Improved system efficiency: By maintaining consistent flow or pressure levels, the switch ensures that the water system operates at its good performance.

b. Enhanced safety: Over-pressurization or excessive flow can lead to leaks, damage, and other hazards, and the switch helps prevent this by deactivating the pump when necessary.

c. Extended equipment life: Consistent flow or pressure levels reduce wear and tear on water pumps and other water-related equipment, professional to a longer lifespan.

d. Cost savings: Efficient operation and reduced wear and tear can result in lower energy consumption and maintenance costs.

The electric air pressure switches and electric water pump switches play a crucial role in the efficient and reliable operation of air and water systems in various industrial applications. By maintaining consistent pressure or flow levels, these devices ensure good performance, enhanced safety, extended equipment life, and cost savings.

-

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

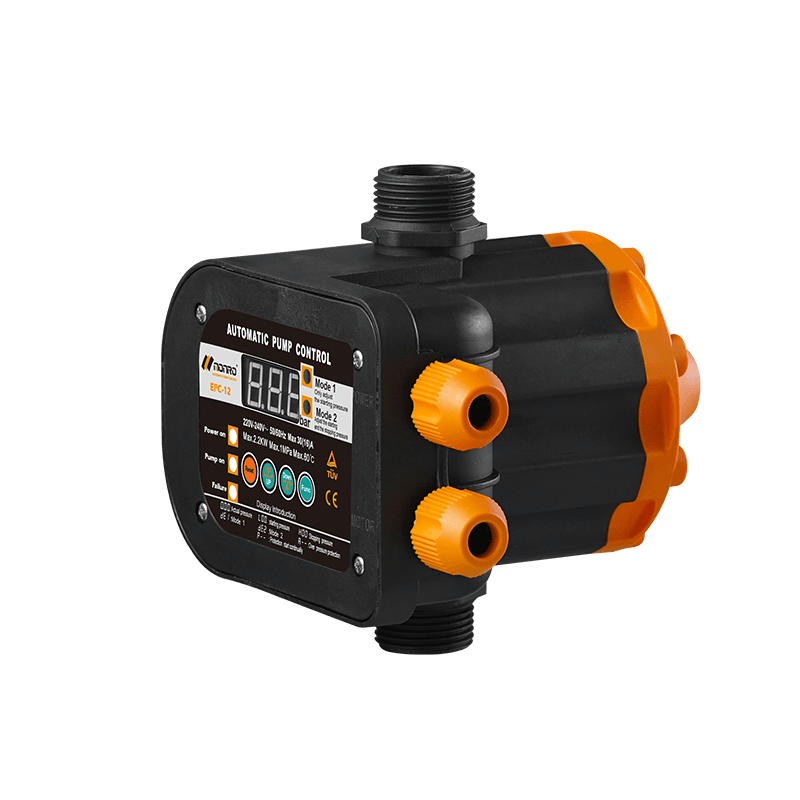

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español