Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Analyzing the Temperature Adaptability of Products of Pressure Switch Factory

ODM Pressure Control Switch Factory Manufacturing Supplier

The adaptability of Pressure Switch Factory's pressure switches in varying temperature conditions is a critical aspect of their performance in the field. As industries demand robust and reliable pressure monitoring equipment that can withstand a range of environmental conditions, the Pressure Switch Factory has risen to the challenge by engineering switches that are adaptable to different temperature extremes. This article will explore the design features, materials, and testing processes that contribute to the temperature adaptability of the Pressure Switch Factory's products.

The Pressure Switch Factory is renowned for its commitment to manufacturing pressure switches that can operate efficiently in a wide range of temperatures. From the Arctic chill to the scorching heat of desert environments, these switches are designed to maintain their calibration and functionality without fail. The adaptability of Pressure Switch Factory's products is a result of rigorous material selection and engineering practices that account for thermal expansion and contraction, as well as the potential for corrosion or material fatigue at bad temperatures.

The materials used in the construction of Pressure Switch Factory's switches are chosen for their thermal stability and resistance to degradation over time. High-quality stainless steel, for instance, is a common choice due to its resistance to corrosion and its ability to maintain structural integrity across a broad temperature spectrum. Additionally, the use of temperature-resistant seals and gaskets ensures that the internal mechanisms of the switches are protected from external temperature fluctuations.

The design of Pressure Switch Factory's pressure switches also plays a significant role in their temperature adaptability. The switches are often designed with a chamber that isolates the pressure-sensing element from the external environment, thereby reducing the impact of temperature variations on the internal components. This design feature, coupled with the use of temperature compensation algorithms, allows the switches to maintain their accuracy and stability even when subjected to rapid temperature changes.

Testing is an integral part of the Pressure Switch Factory's process, ensuring that each switch is capable of operating within its specified temperature range. The factory conducts a series of tests, including thermal shock testing, where switches are exposed to sudden changes in temperature to simulate real-world conditions. This helps to identify any potential weaknesses in the design or materials that could compromise the switch's performance under bad temperature conditions.

Furthermore, the Pressure Switch Factory's commitment to quality extends to its calibration procedures, which are performed at specific temperature points to account for any potential deviations in performance. This ensures that each switch is calibrated to provide accurate readings across its entire operational temperature range.

In conclusion, the Pressure Switch Factory's focus on temperature adaptability is a testament to its dedication to producing high-quality pressure switches. Through careful material selection, innovative design, and rigorous testing, the Pressure Switch Factory ensures that their products can be relied upon in a variety of temperature conditions, providing industries with dependable pressure monitoring solutions. As the need for resilient and reliable pressure switches continues to grow, the Pressure Switch Factory remains at the forefront of temperature-resistant pressure switch technology.

-

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

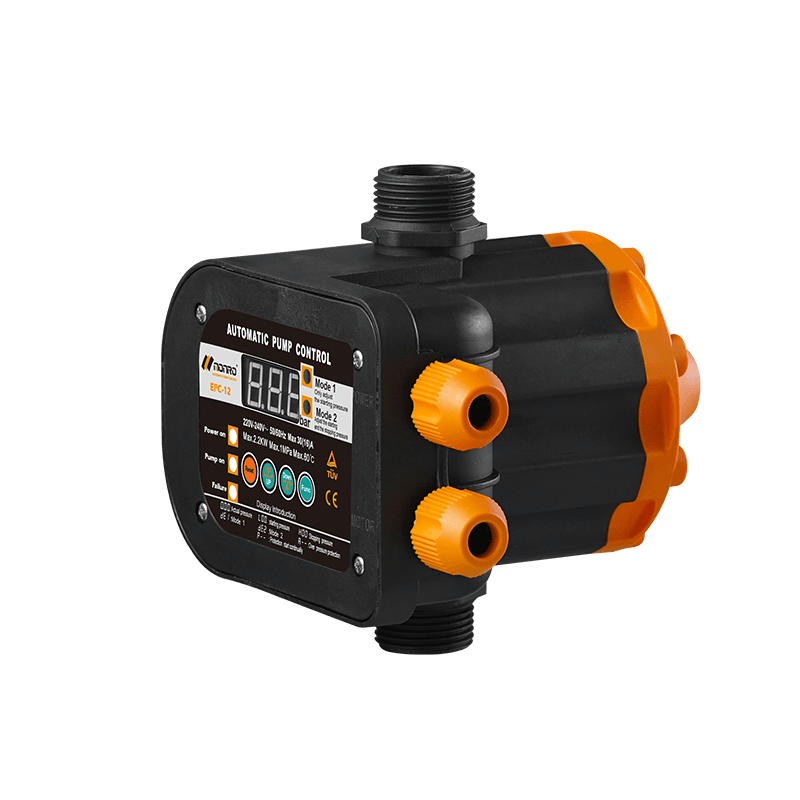

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español