Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Automatic Motor Pump Controllers and Automatic Submersible Pump Controllers in Modern Water Management Systems

Water management is a critical aspect of various industries, including agriculture, construction, and municipal water supply. The efficient and reliable operation of water pumps is essential to ensure the smooth functioning of these systems.

1. Overview of Automatic Motor Pump Controllers

Automatic Motor Pump Controllers are electronic devices designed to control the operation of motor-driven pumps. They are responsible for starting, stopping, and monitoring the performance of the pumps, ensuring that they operate within the desired parameters. These controllers are essential in maintaining the efficiency and reliability of the pumping system.

2. Overview of Automatic Submersible Pump Controllers

Automatic Submersible Pump Controllers are specifically designed for submersible pumps, which are used in various applications such as water supply, sewage treatment, and dewatering. These controllers offer similar functionalities as motor pump controllers but are tailored to the unique requirements of submersible pumps.

3. Key Functions of Automatic Motor Pump Controllers and Automatic Submersible Pump Controllers

a. Automatic Start/Stop: Both controllers are programmed to start and stop the pumps based on specific conditions, such as water level or pressure. This ensures that the pumps operate only when necessary, reducing energy consumption and wear on the equipment.

b. Overload Protection: These controllers are equipped with overload protection features that prevent damage to the pumps and motors in case of excessive current draw.

c. Dry Run Protection: Automatic Motor Pump Controllers and Automatic Submersible Pump Controllers monitor the flow of water through the pumps and stop the operation if the flow drops below a certain threshold, preventing dry running and potential damage to the pumps.

d. Fault Detection: These controllers are designed to detect and diagnose various faults in the pumping system, such as leaks, blockages, and motor failures, and alert the operator to take appropriate action.

e. Remote Monitoring and Control: Many Automatic Motor Pump Controllers and Automatic Submersible Pump Controllers offer remote monitoring and control capabilities, allowing operators to monitor the performance of the pumps and make adjustments from a central location.

4. Benefits of Using Automatic Motor Pump Controllers and Automatic Submersible Pump Controllers

a. Energy Efficiency: By controlling the operation of the pumps based on specific conditions, these controllers help reduce energy consumption and lower operating costs.

b. Increased Reliability: The use of these controllers ensures that the pumps operate within their designed parameters, reducing the risk of failures and extending the lifespan of the equipment.

c. Reduced Maintenance Costs: The built-in protection features of these controllers help prevent damage to the pumps and motors, reducing the need for frequent repairs and maintenance.

d. Improved Safety: Automatic Motor Pump Controllers and Automatic Submersible Pump Controllers help prevent accidents and injuries by ensuring that the pumps operate safely and within their designed parameters.

e. Enhanced Water Management: These controllers enable more efficient and effective water management by providing precise control over the operation of the pumps, ensuring that the water supply meets the required demands.

5. Applications of Automatic Motor Pump Controllers and Automatic Submersible Pump Controllers

a. Agricultural Irrigation: These controllers are used to manage the operation of irrigation pumps, ensuring that crops receive the right amount of water at the right time.

b. Municipal Water Supply: Automatic Motor Pump Controllers and Automatic Submersible Pump Controllers are used in municipal water supply systems to maintain consistent water pressure and flow.

c. Sewage Treatment: In sewage treatment plants, these controllers help manage the operation of pumps that transfer wastewater between different treatment stages.

d. Industrial Applications: Various industries, such as mining and manufacturing, use these controllers to manage the operation of pumps that transfer water for cooling, processing, and other purposes.

e. Construction Dewatering: Automatic Submersible Pump Controllers are used in construction projects to remove excess water from excavation sites, ensuring safe and efficient construction operations.

Automatic Motor Pump Controllers and Automatic Submersible Pump Controllers play a crucial role in modern water management systems.

-

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

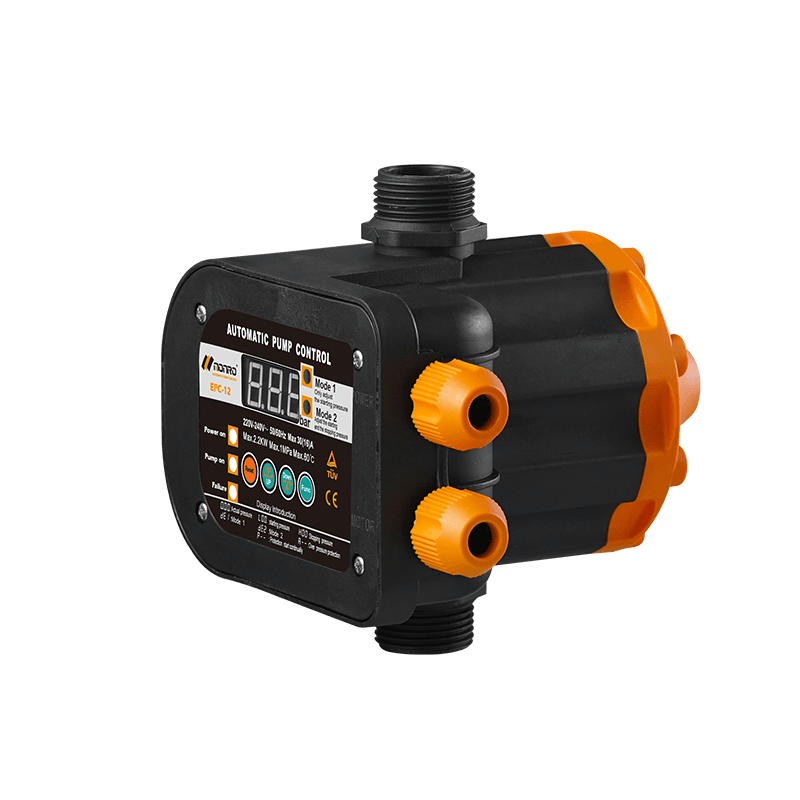

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español