Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Calibration Process of Wholesale Pressure Switches Ensuring Precision and Reliability

High Quality Wholesale Pressure Switch Company in China

Calibration is a critical process for the Wholesale Pressure Switch, ensuring that it provides accurate and reliable pressure readings across a range of applications. This process is essential for maintaining the integrity of systems that rely on precise pressure control, from industrial processes to safety monitoring. Understanding the calibration process of Wholesale Pressure Switches is vital for technicians and engineers who are responsible for their installation, maintenance, and operation.

The calibration process begins with the selection of a suitable calibration standard, which is a device that provides a known pressure value for comparison. This standard is typically a precision pressure gauge or a deadweight tester, which is used to apply a known pressure to the Wholesale Pressure Switch. The switch is then adjusted so that its output matches the known pressure value of the calibration standard.

During the calibration process, the Wholesale Pressure Switch is subjected to a series of pressure points and any intermediate set points that are relevant to its operation. At each pressure point, the switch's output is compared to the calibration standard, and any discrepancies are corrected. This may involve adjusting the switch's internal components, such as the spring or diaphragm, to ensure that the output signal accurately reflects the applied pressure.

The calibration process also involves testing the switch's repeatability and hysteresis. Repeatability refers to the ability of the Wholesale Pressure Switch to provide the same output for a given pressure input over multiple tests. Hysteresis is the difference in pressure readings when the pressure is increased and then decreased, or vice versa. Both of these factors are important for ensuring that the switch provides consistent and reliable pressure readings.

In addition to the mechanical adjustments, the calibration process may also involve configuring the switch's electronic components. Many modern Wholesale Pressure Switches have digital outputs, which can be programmed to provide specific signals at certain pressure thresholds. This programming is done using a calibration tool or software, which allows technicians to set the desired output values for each pressure set point.

Once the mechanical and electronic adjustments have been made, the Wholesale Pressure Switch is tested again to ensure that it meets the required accuracy and repeatability specifications. This may involve applying pressure cycles to the switch and monitoring its output to confirm that it remains within the specified tolerances.

The calibration process is not a one-time event; it should be repeated regularly to maintain the accuracy and reliability of the Wholesale Pressure Switch. The frequency of calibration depends on various factors, including the switch's operating environment, the criticality of the application, and the manufacturer's recommendations.

In conclusion, the calibration process of Wholesale Pressure Switches is a meticulous procedure that ensures the switches provide accurate pressure readings. It involves the use of calibration standards, mechanical adjustments, electronic configuration, and rigorous testing to guarantee that the switches perform as expected in their applications. By understanding and following the calibration process, technicians can ensure that Wholesale Pressure Switches contribute to the safe and efficient operation of the systems they are a part of.

-

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

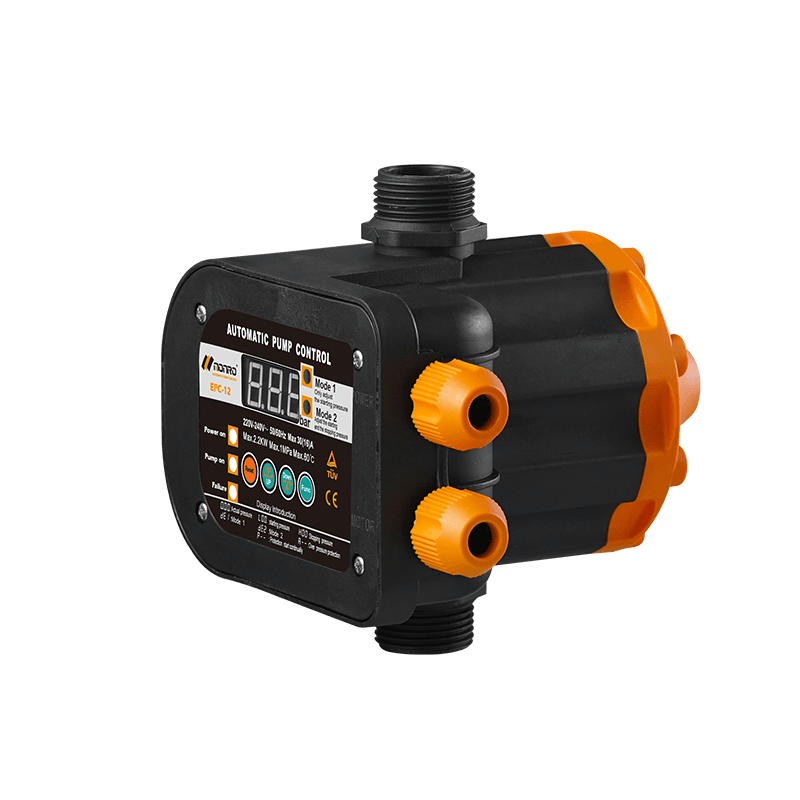

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español