Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Performance of Wholesale Pressure Switches Across Diverse Media in Industrial Settings

Custom Wholesale Pressure Switch Manufacturing Supplier

The performance of the Wholesale Pressure Switch is a pivotal consideration for industries that rely on precise pressure monitoring and control. These switches are engineered to operate in a variety of media, including gases, liquids, and even slurries, making them indispensable in numerous industrial applications. The versatility of Wholesale Pressure Switches is a testament to their design, which must accommodate the unique challenges posed by different media without compromising on accuracy or reliability.

In the context of gaseous media, Wholesale Pressure Switches must be capable of detecting minute changes in pressure without being affected by the compressibility of gases. This requires a high degree of sensitivity and precision, which is often achieved through the use of advanced sensing technologies. For instance, some switches employ diaphragm-based sensors that can flex in response to pressure changes, providing a reliable and consistent signal output.

When it comes to liquid media, the challenges are somewhat different. Liquids, being incompressible, exert a more consistent pressure on the Wholesale Pressure Switch. However, the viscosity of the liquid can affect the switch's performance. High-viscosity liquids may require a switch with a more robust design to withstand the additional stress. Additionally, the presence of particulates or contaminants in the liquid can impact the longevity and accuracy of the switch, necessitating the use of filters or other protective measures.

The performance of Wholesale Pressure Switches in slurries or other abrasive media presents a unique set of challenges. The abrasive nature of these media can cause wear and tear on the switch's components, causing reduced accuracy and a shorter lifespan. To counteract this, manufacturers often use materials that are resistant to abrasion, such as stainless steel or other hard-wearing alloys. Furthermore, the design of the switch may incorporate features that minimize contact with the abrasive particles, such as recessed sensing elements or protective coatings.

Temperature is another factor that can significantly impact the performance of Wholesale Pressure Switches. Extreme temperatures can cause materials to expand or contract, affecting the switch's sensitivity and response time. To ensure consistent performance across a range of temperatures, switches may be designed with temperature compensation features or made from materials that exhibit thermal expansion.

The environmental conditions in which Wholesale Pressure Switches operate can also influence their performance. Humidity, corrosive gases, and other environmental factors can degrade the switch's components over time. To mitigate these effects, switches may be sealed or coated with materials that protect against corrosion and moisture.

In addition to the physical properties of the media, the operational requirements of the system in which the Wholesale Pressure Switch is installed must also be considered. The switch must be able to withstand the pressures, temperatures, and other conditions that it will encounter in its specific application. This may involve customizing the switch to meet the unique demands of the system, such as adjusting the pressure range, response time, or output signal.

The calibration of Wholesale Pressure Switches is another critical aspect of their performance. Accurate calibration ensures that the switch provides reliable readings and responds appropriately to pressure changes. This process typically involves testing the switch under controlled conditions to verify its accuracy and adjust its settings as needed.

Maintenance and servicing are also essential for maintaining the performance of Wholesale Pressure Switches. Regular inspections and cleaning can help to identify and address any issues before they become critical, prolonging the life of the switch and ensuring its continued reliability.

In conclusion, the performance of Wholesale Pressure Switches in different media is a complex interplay of design, materials, calibration, and maintenance. By understanding the specific challenges posed by each type of media and taking the necessary steps to address them, manufacturers can ensure that their Wholesale Pressure Switches provide consistent and reliable performance in a wide range of industrial applications.

-

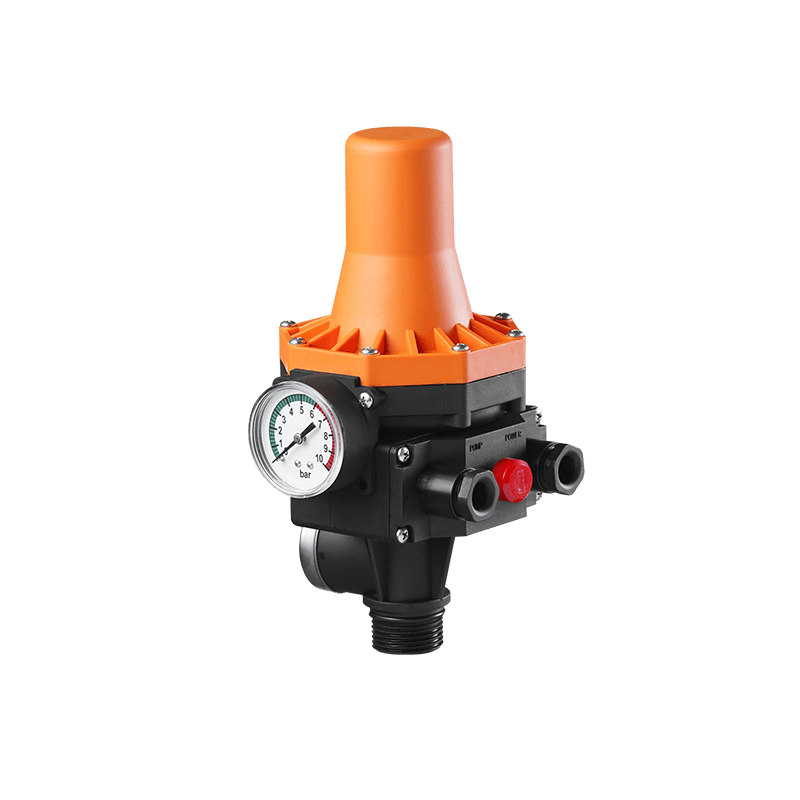

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español