Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

In-depth Analysis of the Working Principle of Water Pump Controllers

Wholesale Float Pressure Water Pump Controller Producer

The Water Pump Controller is an essential component in various applications, from domestic water supply systems to large-scale industrial processes. Its primary function is to regulate the operation of water pumps, ensuring efficient and effective water flow. Understanding the working principle of a Water Pump Controller is crucial for its proper application and maintenance. This article delves into the intricacies of how these controllers operate, highlighting their importance in modern water management systems.

A Water Pump Controller typically operates on the principle of feedback control, which involves monitoring the system's performance and adjusting the pump's operation accordingly. The controller receives input signals that indicate the water level, pressure, or flow rate in the system. Based on these inputs, the controller determines whether the pump needs to start, stop, or adjust its speed to maintain the desired water flow.

One of the common types of Water Pump Controllers is the pressure-based controller. In this setup, a pressure sensor is installed in the water distribution system. The sensor detects the pressure and sends this information to the controller. If the pressure drops below a preset threshold, the controller activates the pump to increase the pressure. Conversely, if the pressure exceeds the set limit, the controller turns off the pump to prevent over-pressurization, which can cause system damage.

Another type of Water Pump Controller is the float switch controller, which uses a float mechanism to detect water levels in a tank or reservoir. As the water level rises or falls, the float moves up or down, triggering the pump to start or stop. This type of controller is often used in wells, sumps, and other applications where maintaining a constant water level is critical.

Flow-based Water Pump Controllers are designed to regulate the flow of water rather than pressure. These controllers use flow meters to measure the water flow rate. If the flow rate is too low, the controller increases the pump speed to boost the flow. If the flow rate is too high, the controller reduces the pump speed to prevent over-pumping.

Modern Water Pump Controllers often incorporate advanced features such as variable frequency drives (VFDs), which allow for precise speed control of the pump motor. This not only optimizes the pump's performance but also saves energy by matching the pump's output to the system's demand. VFDs enable the Water Pump Controller to softly start the pump, reducing wear and tear and extending the pump's lifespan.

Communication capabilities are also a significant aspect of contemporary Water Pump Controllers. Many controllers can be integrated into a building's automation system, allowing for remote monitoring and control. This integration enables facility managers to monitor the performance of the Water Pump Controller and make adjustments as needed, ensuring suitable operation and reducing downtime.

In conclusion, the working principle of a Water Pump Controller is centered around the regulation of water flow, pressure, or level, depending on the type of controller. By continuously monitoring system parameters and adjusting the pump's operation, these controllers ensure efficient water management. The integration of advanced technologies like VFDs and communication capabilities has further enhanced the performance and reliability of Water Pump Controllers, making them indispensable in today's water management systems.

-

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

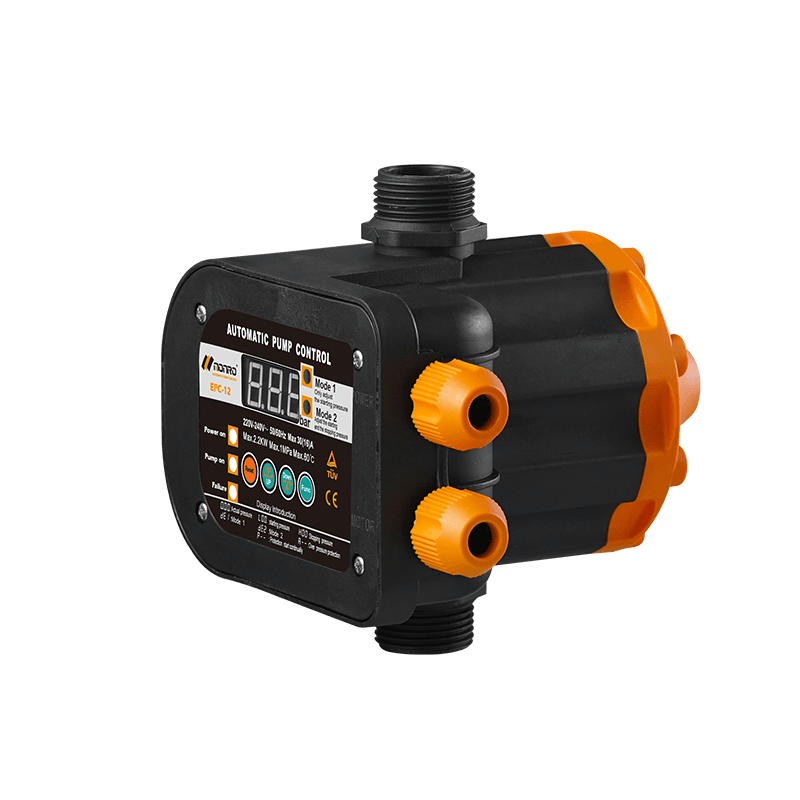

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español