Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Enhancing Precision in China Pressure Switch Applications for Performance

Design Sale China Pressure Switch Manufacturing Factory

The China Pressure Switch, a critical element in various industrial and commercial systems, is designed to provide precise pressure monitoring and control. Ensuring a high level of accuracy in its operation is essential for maintaining the efficiency and safety of these systems. This article discusses various strategies and considerations for improving the use precision of China Pressure Switches, highlighting the importance of calibration, maintenance, and technological advancements.

The foundation of precision in any pressure switch lies in its calibration. Regular calibration of China Pressure Switches ensures that they provide accurate readings under varying conditions. Calibration should be performed by industry standards and manufacturer guidelines, using certified reference equipment to verify the switch's performance.

Environmental conditions can significantly impact the precision of China Pressure Switches. Temperature, humidity, and vibration are common factors that can cause deviations in readings. Implementing measures to control these environmental variables, such as using temperature-compensating devices or installing the switch in a stable location, can enhance its accuracy.

The materials used in the construction of China Pressure Switches play a vital role in their durability and precision. High-quality materials, such as stainless steel and brass, offer better resistance to corrosion and wear, which can degrade the switch's performance over time. Additionally, the precision of the internal components, including diaphragms and seals, directly affects the accuracy of the pressure readings.

Advancements in sensor technology and microelectronics have led to the development of more sophisticated China Pressure Switches. These innovations allow for higher resolution, faster response times, and improved stability. Incorporating technology in pressure switches can significantly enhance their precision and reliability.

Proper maintenance is crucial for maintaining the precision of China Pressure Switches. Regular cleaning and inspection can prevent the buildup of debris and corrosion, which can affect the switch's performance. Additionally, replacing worn-out parts and ensuring that the switch is free from leaks and damage can help maintain its accuracy.

The integration of China Pressure Switches with advanced control systems can further improve their precision. These systems can provide real-time monitoring, data logging, and automated adjustments to compensate for any deviations in pressure readings. The use of software algorithms can also help in filtering out noise and providing more accurate pressure measurements.

The operators and technicians responsible for the use and maintenance of China Pressure Switches should be well-trained and knowledgeable about their operation. Understanding the principles of pressure measurement, the specific features of the switch, and the practices for calibration and maintenance can significantly contribute to the precision of the switch.

Manufacturers of China Pressure Switches should adhere to strict quality control measures and comply with international standards. This ensures that the switches are designed and manufactured to meet high levels of precision and reliability. Regular audits and certifications can assure end-users about the quality and performance of the switches.

In conclusion, improving the use precision of China Pressure Switches involves a multifaceted approach that includes regular calibration, consideration of environmental factors, use of high-quality materials, adoption of technological innovations, proper maintenance, integration with control systems, training of personnel, and adherence to quality control standards. By implementing these strategies, users can ensure that their China Pressure Switches provide accurate and reliable pressure monitoring and control, contributing to the overall efficiency and safety of their systems.

-

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

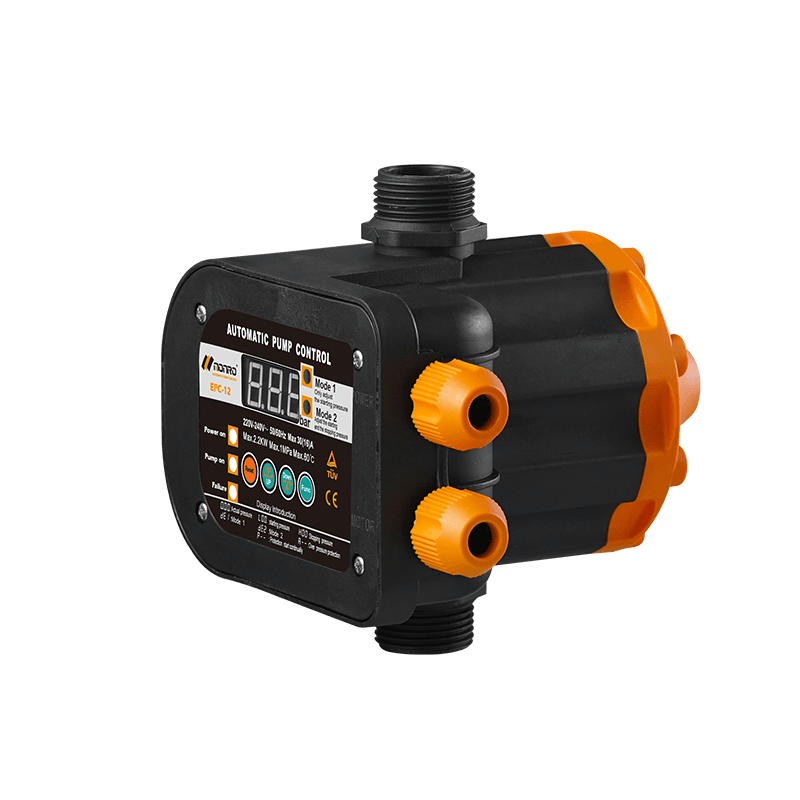

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español