Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Assessing the Precision of Wholesale Pressure Switches in Industrial Automation Systems

China High Quality OEM Wholesale Pressure Switch Exporter

In the intricate world of industrial automation, the precision of Wholesale Pressure Switch is a critical parameter that determines the efficiency and reliability of various processes. These switches, integral to monitoring and controlling pressure levels, must exhibit high accuracy to ensure that systems operate within the desired parameters. The precision of Wholesale Pressure Switches is a complex attribute, influenced by a multitude of factors including design, manufacturing quality, and environmental conditions.

The accuracy of a Wholesale Pressure Switch is often measured by its ability to detect minute changes in pressure and respond accordingly without delay. This is crucial in applications where even slight deviations from the set pressure can cause significant operational issues. For instance, in the chemical industry, where reactions are highly sensitive to pressure changes, the precision of Wholesale Pressure Switches can directly impact the quality of the end product.

Manufacturers of Wholesale Pressure Switches invest heavily in research and development to enhance their precision. This involves the use of advanced materials that can withstand the corrosive nature of certain media, as well as the implementation of sophisticated algorithms that can quickly process and respond to pressure data. The switches are also designed to minimize hysteresis, which is the difference in pressure readings when the switch is actuated in opposite directions. This is particularly important in applications where the pressure can fluctuate rapidly, such as in hydraulic systems.

The calibration of Wholesale Pressure Switches is another aspect that contributes to their precision. Calibration involves adjusting the switch to ensure that it provides accurate readings under specific conditions. This process is typically carried out by the manufacturer, but it can also be performed by end-users if they have the necessary equipment and expertise. Regular calibration is essential to maintain the precision of Wholesale Pressure Switches, as environmental factors and wear and tear can affect their performance over time.

In addition to calibration, the precision of Wholesale Pressure Switches can be influenced by the quality of the sensors used. High-quality sensors are more sensitive and can detect even slight changes in pressure, causing more accurate readings. However, these sensors are also more expensive, which can be a consideration for companies looking to balance cost and performance.

Environmental factors also play a significant role in the precision of Wholesale Pressure Switches. Temperature fluctuations, for example, can affect the performance of the switch, as can the presence of moisture or other contaminants. To mitigate these effects, switches may be designed with specific materials or coatings that are resistant to such conditions. Additionally, some switches may be equipped with temperature compensation features that adjust the readings based on the ambient temperature.

The precision of Wholesale Pressure Switches is also affected by their mounting and installation. Proper installation ensures that the switch is aligned correctly with the pressure source, which can help to reduce errors. Furthermore, the switch should be mounted in a way that decreases the risk of damage from physical impacts or vibrations, which can also affect its accuracy.

In conclusion, the precision of Wholesale Pressure Switches is a multifaceted attribute that is influenced by a variety of factors, including design, materials, calibration, sensor quality, environmental conditions, and installation. Manufacturers and users alike must consider these factors when selecting and using Wholesale Pressure Switches to ensure that they meet the required levels of accuracy for their specific applications. By doing so, they can help to maintain the efficiency and reliability of industrial processes, ultimately contributing to the overall success of the operations in which they are employed.

-

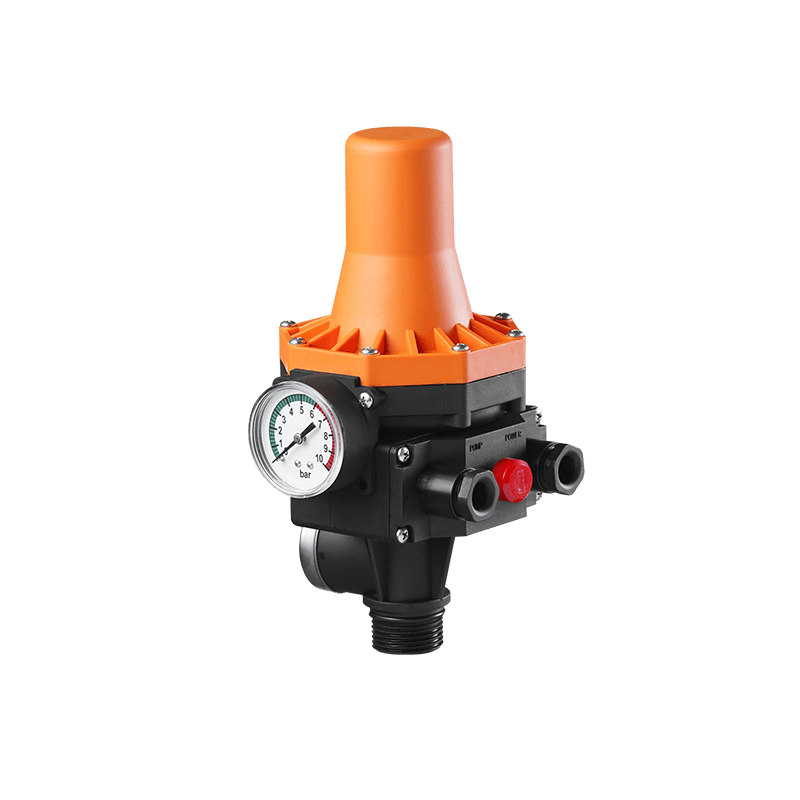

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español