Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Investigating the Response Time Speed of Wholesale Pressure Switches in Dynamic Industrial Environments

Sale ODM Wholesale Pressure Switch Manufacturer in China

In fast-paced and dynamic industrial environments, the response time speed of the Wholesale Pressure Switch is a crucial factor that can significantly impact the overall performance and safety of a system. These switches are designed to detect changes in pressure and respond accordingly, often within milliseconds, to ensure that processes are maintained within safe and efficient parameters. The speed at which a Wholesale Pressure Switch can detect and react to pressure changes is a measure of its responsiveness, which is a key performance indicator in the field of industrial automation.

The response time of a Wholesale Pressure Switch is influenced by several factors, including the type of sensor used, the quality of the electronics, and the design of the switch itself. High-quality switches are engineered to decrease delay, ensuring that they can react almost instantaneously to changes in pressure. This is particularly important in applications where rapid changes in pressure can cause catastrophic failures or significant inefficiencies.

One of the primary considerations in the design of Wholesale Pressure Switches is the type of sensor used. There are various types of sensors available, each with its advantages and disadvantages in terms of response time. For instance, piezoelectric sensors are known for their quick response times, making them ideal for applications where rapid detection of pressure changes is critical. On the other hand, capacitive sensors may offer a slower response but provide greater accuracy over a wider range of pressures.

The electronics within a Wholesale Pressure Switch also play a significant role in determining its response time. Advanced microcontrollers and signal processing circuits can process the sensor data quickly, allowing the switch to respond almost immediately to changes in pressure. However, the complexity of the electronics can also introduce additional delays, which is why careful design and optimization are necessary to ensure that the response time remains as fast as possible.

The physical design of the Wholesale Pressure Switch is another factor that can affect its response time. The switch must be able to withstand the pressures it is designed to monitor, and this often requires a robust and durable construction. However, the materials and construction methods used can also impact the speed at which the switch can respond to pressure changes. For example, a switch with a large diaphragm may take longer to respond to pressure changes than one with a smaller, more sensitive diaphragm.

In addition to the design and construction of the Wholesale Pressure Switch, the environment in which it operates can also influence its response time. Factors such as temperature, humidity, and the presence of contaminants can all affect the performance of the switch. For example, bad temperatures can cause materials to expand or contract, which can slow down the response time of the switch. Similarly, high levels of humidity or the presence of corrosive substances can degrade the performance of the electronics, causing slower response times.

To ensure that Wholesale Pressure Switches meet the required response time specifications, manufacturers often subject them to rigorous testing and quality control procedures. This can include testing the switches under a variety of conditions to ensure that they perform consistently and reliably. Additionally, many manufacturers offer customization options, allowing customers to specify the exact response time requirements for their specific applications.

In conclusion, the response time speed of Wholesale Pressure Switches is a critical aspect of their performance in industrial settings. It is influenced by a variety of factors, including the type of sensor used, the quality of the electronics, the physical design of the switch, and the operating environment. By understanding these factors and working closely with manufacturers, it is possible to select or design Wholesale Pressure Switches that meet the specific response time requirements of any given application, ensuring suitable performance and safety.

-

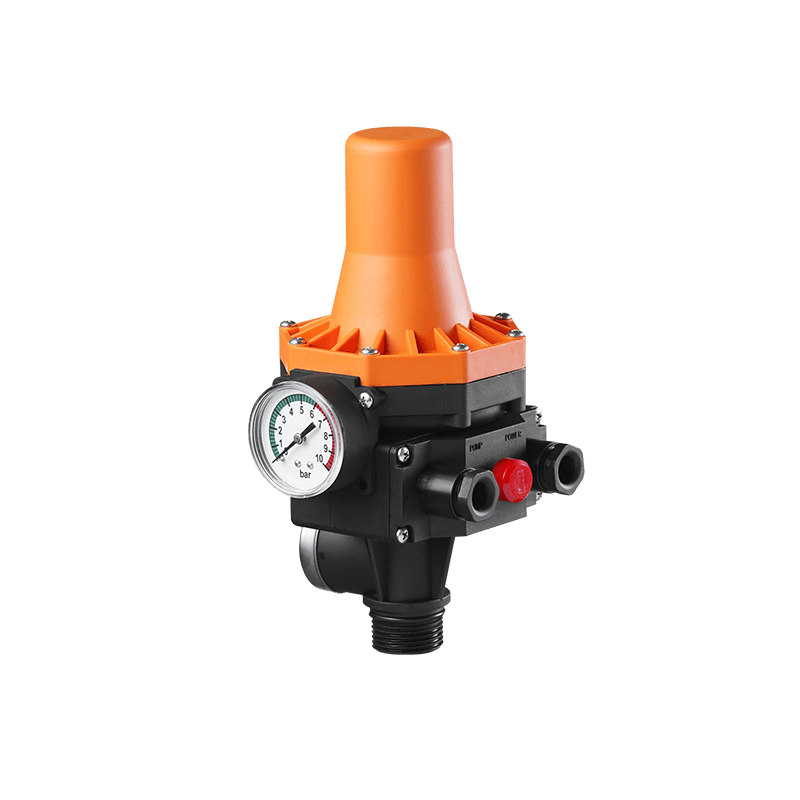

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español