Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

The Integral Role of Float Switch Suppliers in Water Treatment Systems

Sale Pressure Float Switch Supplier Manufacturing Factory

In the intricate world of water treatment systems, the float switch stands as a vital component, ensuring the smooth operation and safety of the entire process. Float switch supplier plays a crucial role in providing these essential devices, which are designed to monitor and control the level of water in various tanks, reservoirs, and treatment facilities. This article explores the multifaceted functions of float switches in water treatment systems and the indispensable role of float switch suppliers in ensuring their effectiveness, reliability, and safety.

Water treatment systems are complex networks of equipment and processes designed to purify water for various uses, including drinking, irrigation, and industrial applications. A critical aspect of these systems is the management of water levels, which is where float switches come into play. Float switches, supplied by specialized float switch suppliers, are devices that use the buoyancy of a float to detect the level of liquid in a container. When the water level rises or falls to a certain point, the float actuates a switch, triggering an alarm, starting or stopping a pump, or initiating other necessary actions.

Float switch suppliers are responsible for the design, manufacturing, and distribution of these devices. They must ensure that the float switches they provide are tailored to the specific needs of water treatment systems, taking into account factors such as the type of liquid, the size of the container, and the required level of accuracy. The suppliers must also guarantee that their products are made from materials that can withstand the corrosive nature of water and the chemicals used in treatment processes.

One of the primary functions of float switches in water treatment systems is to prevent overflow. In a water storage tank, for example, a float switch can be installed to monitor the water level and automatically shut off the inflow when the tank is full. This prevents water from spilling over and causing damage to the surrounding infrastructure or environment. Float switch suppliers must ensure that their products are sensitive enough to detect even minor changes in water level, thereby preventing overflows effectively.

Another critical application of float switches in water treatment systems is in the control of pumps. Float switches can be used to start a pump when the water level in a tank drops below a certain point, ensuring a continuous supply of water to the treatment process. Conversely, they can also be used to stop the pump when the water level reaches a certain height, preventing the pump from running dry and causing damage. Float switch suppliers must provide devices with precise control capabilities to ensure that pumps operate efficiently and safely.

In addition to preventing overflows and controlling pumps, float switches also play a role in the monitoring and alert systems of water treatment facilities. They can be connected to alarms or other warning systems to notify operators of abnormal water levels, which could indicate a problem in the treatment process. This allows for prompt action to be taken, reducing the risk of equipment damage or process disruption. Float switch suppliers must ensure that their products are compatible with various alarm systems and can provide clear, reliable signals in the event of an issue.

The reliability of float switches in water treatment systems is heavily dependent on the quality of the products supplied by float switch suppliers. These suppliers must adhere to strict quality control standards, ensuring that their devices are durable, accurate, and resistant to the harsh conditions found in water treatment facilities. They must also provide ongoing support and maintenance services to ensure that the float switches continue to function effectively over time.

Furthermore, float switch suppliers must stay abreast of technological advancements and industry trends, incorporating new features and improvements into their products. This could include the development of smart float switches that can communicate with other devices in the water treatment system, providing real-time data and enhancing the overall efficiency and safety of the process.

In conclusion, float switch suppliers play a vital role in the operation of water treatment systems, providing essential devices that ensure the safety, efficiency, and reliability of these critical facilities. By offering high-quality products, adhering to strict quality control standards, and staying at the forefront of technological advancements, float switch suppliers contribute significantly to the success of water treatment processes worldwide.

-

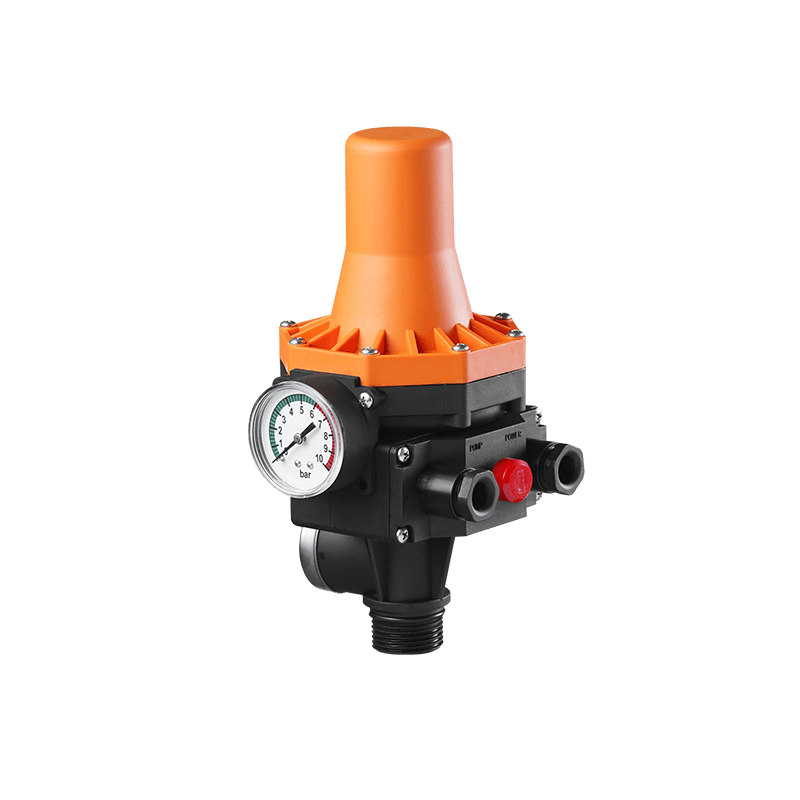

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español