Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Ensuring Safety and Reliability in Float Switches of Float Switch Suppliers

High Quality OEM Pressure Float Switch Supplier in China

In the realm of industrial automation and fluid management, the float switch plays a pivotal role in monitoring and controlling the level of liquids in various systems. As a critical component in processes ranging from water treatment to chemical processing, the safety and reliability of float switches are paramount. Float switch supplier, therefore, bears the responsibility of delivering products that meet high standards of performance and dependability. This article delves into the various measures and strategies employed by float switch suppliers to ensure the safety and reliability of their products.

Float Switch Supplier must adhere to stringent quality control protocols. This begins with the selection of raw materials, where suppliers must source components that are resilient, resistant to corrosion, and compatible with the fluids they will be exposed to. The manufacturing process itself is subject to rigorous inspection and testing at every stage to ensure that each float switch is built to precise specifications and free from defects.

In addition to quality control, float switch suppliers invest in research and development to innovate and improve their products. By staying at the forefront of technological advancements, these suppliers can incorporate new materials, designs, and features that enhance the safety and reliability of their float switches. For instance, the use of advanced polymers can provide better resistance to chemical corrosion, while innovative designs can improve the switch's sensitivity and response time.

Another critical aspect of ensuring safety and reliability is the adherence to industry standards and certifications. Float switch suppliers must ensure that their products comply with international standards such as ISO, ANSI, and CE, which set benchmarks for safety, performance, and environmental impact. Obtaining these certifications not only validates the quality of the float switches but also instills confidence in customers regarding the product's safety and reliability.

Education and training are also vital components in the浮ball switch suppliers' strategy to ensure product safety and reliability. By providing comprehensive training to their customers, suppliers can ensure that the float switches are installed, operated, and maintained correctly. This reduces the risk of improper use or mishandling, which could compromise the safety and reliability of the float switches.

Furthermore, float switch suppliers must offer robust after-sales support to address any issues that may arise. This includes providing technical support, troubleshooting assistance, and prompt replacement or repair services. By standing behind their products and addressing customer concerns swiftly, float switch suppliers can maintain a reputation for reliability and trustworthiness.

In the context of safety, float switch suppliers must also consider the environmental impact of their products. This involves using environmentally friendly materials and manufacturing processes that decrease waste and pollution. By doing so, suppliers can ensure that their products are not only safe for use in various applications but also sustainable and responsible from an environmental perspective.

Lastly, float switch suppliers must continuously monitor and evaluate the performance of their products in real-world applications. By gathering feedback from customers and analyzing the performance data, suppliers can identify areas for improvement and make necessary adjustments to their products. This ongoing process of evaluation and refinement is crucial for maintaining the safety and reliability of float switches over time.

In conclusion, ensuring the safety and reliability of float switches is a multifaceted endeavor that involves rigorous quality control, innovation, adherence to industry standards, education, after-sales support, environmental responsibility, and continuous performance evaluation. By committing to these practices, float switch suppliers can provide products that are not only safe and reliable but also meet the diverse needs of their customers across various industries.

-

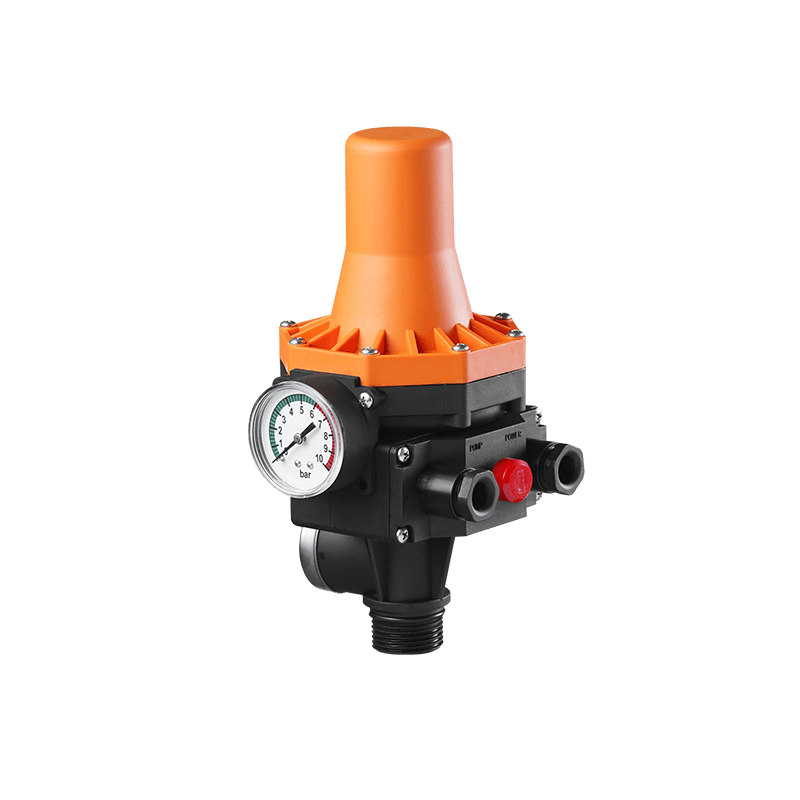

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español