Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Maintaining Performance of Wholesale Pressure Switches in High-Temperature Environments

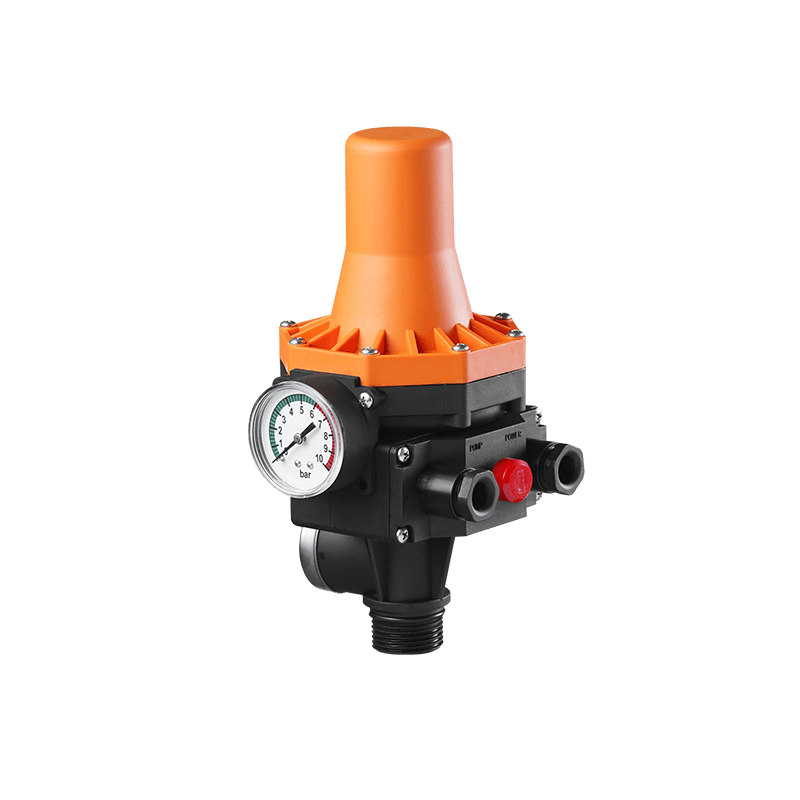

Design Wholesale Pressure Switch Manufacturing Producer

The resilience and performance of the Wholesale Pressure Switch is paramount in industries where high temperatures are the norm. These switches are integral to monitoring and controlling pressure in various applications, from hydraulic systems to industrial processes. The ability of Wholesale Pressure Switches to maintain their performance in high-temperature conditions is a critical factor in ensuring the safety and efficiency of these systems. This article explores the strategies and technologies employed to ensure that Wholesale Pressure Switches continue to function suitably even in the face of heat.

The performance of Wholesale Pressure Switches in high-temperature environments is influenced by several factors, including the materials used in their construction, the design of the switch, and the specific environmental conditions they are subjected to. Manufacturers of Wholesale Pressure Switches must consider these factors when designing their products to ensure they can withstand the rigors of high-temperature operation.

One of the primary considerations in the design of Wholesale Pressure Switches for high-temperature applications is the choice of materials. Materials that can withstand high temperatures without losing their structural integrity or becoming brittle are essential. Common materials used in the construction of Wholesale Pressure Switches include stainless steel, which is known for its corrosion resistance and high-temperature tolerance, and certain grades of plastic that are designed to withstand heat without degrading.

In addition to material selection, the design of Wholesale Pressure Switches also plays a crucial role in their high-temperature performance. Sealing mechanisms must be robust enough to prevent the ingress of high-temperature fluids or gases that could damage the internal components of the switch. Additionally, the design must allow for heat dissipation to prevent the switch from overheating, which could cause inaccurate readings or failure.

The electronics within Wholesale Pressure Switches are also subject to the challenges of high-temperature environments. Sensitive electronic components can be damaged by heat, causing malfunctions or failures. To combat this, manufacturers may use heat-resistant encapsulants or housings to protect the electronics, or they may opt for components that are specifically designed to operate at high temperatures.

Another aspect of maintaining the performance of Wholesale Pressure Switches in high-temperature conditions is the calibration and testing of the switches. Calibration ensures that the switch provides accurate readings under normal operating conditions. However, in high-temperature environments, the switch may need to be recalibrated to account for any changes in its performance due to heat. Regular testing and maintenance are also essential to identify any potential issues before they cause system failures.

The environment in which the Wholesale Pressure Switch is used can also impact its performance. Factors such as the presence of corrosive gases, dust, or other contaminants can affect the switch's ability to function correctly. In such cases, additional protective measures may be necessary, such as the use of filters or protective coatings.

In conclusion, the performance of Wholesale Pressure Switches in high-temperature environments is a complex issue that requires careful consideration of materials, design, and environmental factors. By employing the right strategies and technologies, manufacturers can ensure that their Wholesale Pressure Switches continue to provide reliable and accurate pressure readings, even in demanding conditions. This is crucial for maintaining the safety and efficiency of industrial processes and systems that rely on these switches to monitor and control pressure.

-

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español