Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Assessing the Stability of Automatic Pump Control in High-Pressure Environments

Wholesale Automatic Pump Control Manufacturing Exporter

In the realm of industrial automation, Automatic Pump Control (APC) systems play a crucial role in maintaining the efficiency and safety of fluid management processes. The stability of these systems under high-pressure conditions is a critical factor that determines their reliability and effectiveness. This article delves into the intricacies of how Automatic Pump Control systems perform in high-pressure environments and the measures taken to ensure their stability.

The Automatic Pump Control systems are designed to regulate the flow of fluids in various applications, from water treatment to oil and gas extraction. When operating under high pressure, these systems face unique challenges that can affect their performance. The pressure can cause increased wear and tear on the mechanical components, and it can also affect the accuracy of the sensors and control algorithms that are integral to the Automatic Pump Control.

To ensure the stability of Automatic Pump Control in high-pressure environments, manufacturers employ a range of design and engineering strategies. These include the use of high-strength materials that can withstand the stress induced by pressure, as well as the implementation of advanced sealing technologies to prevent leaks and maintain system integrity. Additionally, the Automatic Pump Control systems are often equipped with pressure compensation mechanisms that adjust the operation of the pump in response to changes in pressure, ensuring a consistent flow rate and preventing damage to the system.

The sensors used in Automatic Pump Control systems are also critical to their performance under high pressure. These sensors must be capable of accurately measuring pressure, flow, and other variables even in the face of bad conditions. To achieve this, sensors are often made from materials that are resistant to corrosion and have a high tolerance for pressure. Furthermore, they are designed to be highly responsive, allowing the Automatic Pump Control system to make rapid adjustments to maintain suitable performance.

The software that drives the Automatic Pump Control systems is another key component in ensuring stability under high pressure. This software must be capable of processing data from the sensors quickly and accurately, making real-time adjustments to the pump's operation. Advanced algorithms are used to predict and compensate for changes in pressure, allowing the Automatic Pump Control system to maintain a stable output even in fluctuating conditions.

Regular maintenance and monitoring are also essential for the stability of Automatic Pump Control systems in high-pressure environments. This includes routine checks of the mechanical components for signs of wear or damage, as well as calibration of the sensors to ensure their accuracy. By monitoring the performance of the Automatic Pump Control system over time, operators can identify potential issues before they cause system failure.

In conclusion, the stability of Automatic Pump Control systems in high-pressure environments is a complex issue that requires a multifaceted approach. From the design of the mechanical components to the sophistication of the software, every aspect of the Automatic Pump Control system must be optimized to handle the challenges of high pressure. By employing robust materials, advanced sensors, and intelligent control algorithms, manufacturers can ensure that Automatic Pump Control systems remain stable and reliable even in demanding conditions. This commitment to well in design and engineering is what makes Automatic Pump Control systems a cornerstone of modern industrial automation.

-

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

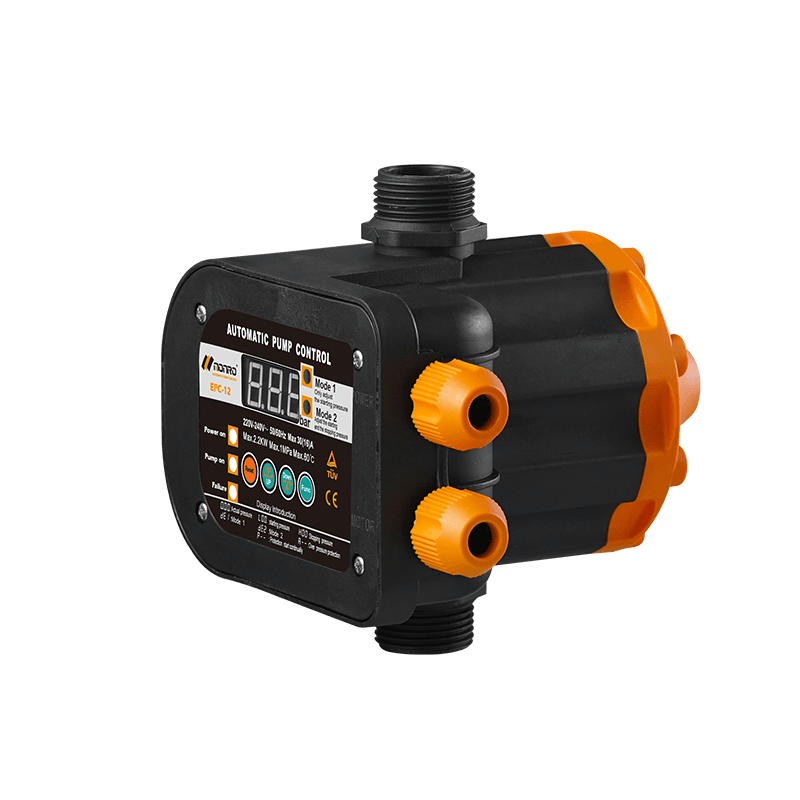

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español