Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Viability of Air Compressor Pressure Control and Regulation in High-Temperature Applications

Air compressor pressure control and regulation play pivotal roles in maintaining good operating conditions and ensuring the efficient performance of compressed air systems. However, when it comes to high-temperature applications, such as industrial furnaces, ovens, or hot air processes, there arise questions regarding the suitability and effectiveness of air compressor pressure switches and regulators.

Air Compressor Pressure Control in High-Temperature Environments:

Functionality and Importance:

Air compressor pressure control mechanisms, including pressure switches and regulators, are essential for maintaining the desired pressure levels within compressed air systems. In high-temperature applications, where thermal expansion and heat dissipation pose significant challenges, the functionality of these components becomes even more critical.

Challenges and Considerations:

High temperatures can adversely affect the performance and reliability of traditional air compressor pressure switches and regulators. Factors such as thermal expansion, heat transfer, and material degradation can lead to inaccurate pressure readings, premature wear, and even system failures. Additionally, the presence of hot air or combustion gases in the vicinity of pressure control components can further exacerbate these challenges.

Solutions and Innovations:

Despite the challenges posed by high temperatures, advancements in materials, design, and technology have led to the development of specialized air compressor pressure control solutions tailored for high-temperature applications. These innovations include:

Heat-resistant materials: Utilizing materials such as stainless steel, brass, or high-temperature plastics in the construction of pressure switches and regulators can enhance their resistance to heat and thermal degradation.

Thermal insulation: Incorporating thermal insulation around pressure control components can help mitigate the effects of heat transfer and thermal expansion, maintaining their accuracy and reliability.

Cooling mechanisms: Implementing active or passive cooling systems, such as heat sinks or airflow channels, can dissipate excess heat generated by pressure control components, ensuring consistent performance in high-temperature environments.

Remote monitoring: Employing remote monitoring and control systems allows operators to monitor pressure levels and adjust settings from a safe distance, minimizing exposure to high temperatures and reducing the risk of damage to pressure control components.

Air Compressor Pressure Switch and Regulator in High-Temperature Applications:

Pressure Switch Functionality:

Pressure switches are crucial components in air compressor systems, responsible for monitoring pressure levels and activating or deactivating the compressor as needed. In high-temperature applications, pressure switches must withstand elevated temperatures and maintain accurate pressure readings to ensure reliable operation.

Pressure Regulator Functionality:

Pressure regulators play a vital role in controlling and stabilizing air pressure downstream of the compressor. In high-temperature environments, pressure regulators must effectively regulate pressure levels while withstanding thermal stress and maintaining consistent performance.

Viability and Considerations:

The viability of using air compressor pressure switches and regulators in high-temperature applications depends on several factors, including the operating temperature range, material compatibility, and the presence of heat shielding or cooling measures. While standard pressure control components may suffice for moderately elevated temperatures, specialized high-temperature variants may be required for more extreme conditions.

The air compressor pressure control and regulation are essential aspects of compressed air systems, ensuring good performance and efficiency. While high-temperature applications present unique challenges, advancements in materials and technology have made it possible to utilize air compressor pressure switches and regulators in such environments effectively. By understanding the challenges, implementing appropriate solutions, and selecting the right components, industries can harness the benefits of air compressor pressure control and regulation in high-temperature applications while ensuring reliability, safety, and efficiency.

-

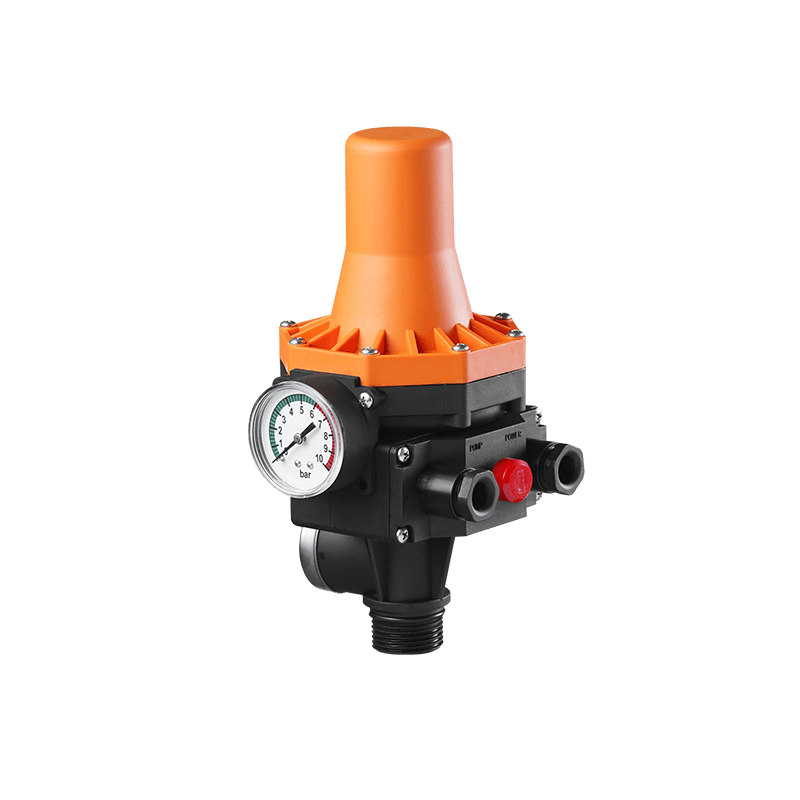

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español