Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

The Role of Motor Pressure Controllers and Switches in Pump Systems

Motor pressure controllers and switches are integral components in pump systems, facilitating the regulation and control of pressure levels to ensure good pump performance and system operation. By monitoring pressure variations and activating or deactivating motors as needed, these devices play a crucial role in maintaining consistent pressure levels, preventing pump damage, and optimizing energy efficiency.

Motor Pressure Controller: Enhancing Pump Performance

Functionality:

A motor pressure controller is a device designed to monitor and regulate pressure levels in pump systems automatically. It typically consists of sensors, control circuits, and motor control mechanisms that adjust motor speed or activation to maintain desired pressure settings.

Pressure Regulation:

The primary function of a motor pressure controller is to regulate pressure levels within pump systems. By continuously monitoring pressure variations and adjusting motor operation accordingly, the controller ensures consistent pressure delivery to downstream equipment or applications.

Energy Efficiency:

Motor pressure controllers contribute to energy efficiency by optimizing motor operation based on demand. By adjusting motor speed or cycling to match pressure requirements, these controllers minimize energy consumption and reduce operating costs over time.

System Protection:

Motor pressure controllers help protect pumps and associated equipment from damage caused by pressure fluctuations or excessive operation. By preventing over-pressurization, dry running, and motor overload, these controllers extend the lifespan of pumps and ensure reliable system operation.

Motor Pressure Switch: Controlling Motor Operation

Activation and Deactivation:

A motor pressure switch is a component that controls the activation and deactivation of motors based on pressure levels in pump systems. When pressure exceeds or falls below preset thresholds, the switch triggers motor operation or shutdown to maintain desired pressure settings.

Pump Control:

Motor pressure switches play a vital role in controlling pump operation by initiating motor start-up or shutdown cycles as needed. These switches ensure that pumps operate only when necessary, minimizing energy consumption and preventing unnecessary wear on pump components.

Pressure Monitoring:

Motor pressure switches continuously monitor pressure levels within pump systems, providing real-time feedback on pressure variations. This information enables operators to identify potential issues, such as leaks or blockages, and take corrective action to maintain system integrity and performance.

Versatile Applications:

Motor pressure switches find applications in various pump systems, including water supply networks, HVAC systems, irrigation systems, and industrial processes. Their versatility and reliability make them indispensable components in ensuring efficient and reliable pump operation across diverse industries.

Motor Pump Switch: Integrating Motor and Pump Control

Seamless Integration:

A motor pump switch combines the functionalities of a motor pressure controller and a motor pressure switch, providing comprehensive control over motor and pump operation in pump systems. This integrated approach streamlines system control and simplifies installation and maintenance.

Dual Functionality:

The motor pump switch not only regulates pressure levels within pump systems but also controls motor activation and deactivation based on pressure variations. This dual functionality ensures precise pressure control and efficient motor operation, maximizing system performance and reliability.

Customizable Settings:

Motor pump switches often feature customizable settings, allowing operators to adjust pressure thresholds, motor start-up delays, and other parameters to suit specific application requirements. This flexibility enables fine-tuning of system performance and optimization of energy efficiency.

Remote Monitoring and Control:

Some motor pump switches offer remote monitoring and control capabilities, allowing operators to monitor pressure levels and adjust system settings from a centralized control panel or mobile device. This remote access enhances convenience, facilitates proactive maintenance, and enables rapid response to changing system conditions.

Conclusion:

Motor pressure controllers, switches, and motor pump switches are essential components in pump systems, providing precise control over pressure levels and motor operation to ensure good performance and reliability. Whether regulating pressure in water supply networks, controlling pumps in HVAC systems, or managing industrial processes, these devices play a cru

-

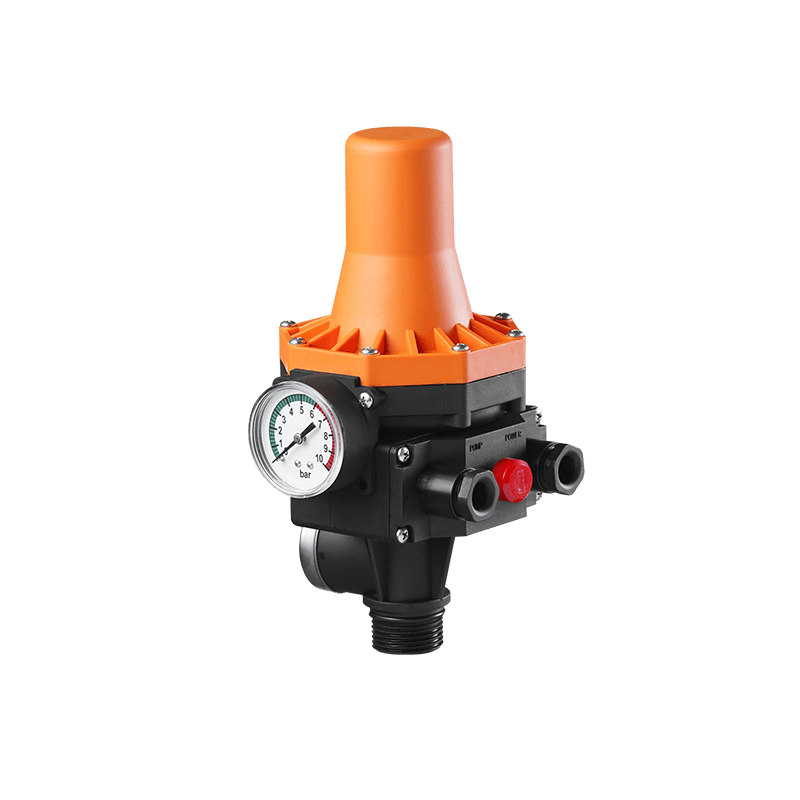

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español