Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Leveraging Automatic Pump Control for Energy Efficiency and Cost Reduction in Industrial Operations

Automatic Pump Control (APC) systems have revolutionized the way businesses manage pumping operations, offering a multitude of benefits ranging from improved energy efficiency to significant cost savings. In this article, we will explore how the integration of real-time data collection, remote monitoring, and automation through Automatic Pump Control can effectively assist enterprises in minimizing energy consumption and operational expenses. By delving into these three crucial aspects, we can comprehend the substantial impact of Automatic Pump Control on resource utilization and financial optimization.

Automatic Pump Control systems leverage automation to optimize pump operation based on real-time data and predefined parameters. Through automated control algorithms, APC can regulate pump speeds, flow rates, and pressure levels to match demand, thereby eliminating unnecessary energy usage and minimizing system inefficiencies. By automatically adjusting pump performance to meet the required output, enterprises can achieve substantial energy savings while maintaining operational effectiveness.

In addition, APC's automation capabilities enable dynamic response to fluctuating demand, ensuring that pumping systems operate at peak efficiency across varying load conditions. By synchronizing pump operations with actual requirements, businesses can avoid overworking pumps at reduced capacity, thereby conserving energy and extending equipment lifespan. The seamless integration of automation within Automatic Pump Control systems plays a pivotal role in streamlining energy usage and optimizing operational costs.

Furthermore, the remote monitoring capabilities of Automatic Pump Control systems enable businesses to oversee their pumping infrastructure from a centralized location. Through web-based dashboards and mobile applications, operators can remotely access real-time data, monitor equipment status, and receive alerts for potential issues or anomalies. This remote visibility allows for proactive maintenance and swift intervention in case of deviations from ideal operating conditions.

By remotely monitoring pump performance and energy usage, enterprises can detect and address inefficiencies without the need for physical inspection of equipment. Timely identification of issues such as pump cavitation, system leaks, or excessive energy consumption empowers maintenance teams to take preemptive measures, preventing costly equipment failures and mitigating unnecessary energy wastage. The ability to remotely monitor and manage pumping operations translates into enhanced reliability, reduced downtime, and ultimately, lower operational costs.

Automatic Pump Control system's ability to gather and analyze real-time data plays a pivotal role in enhancing operational efficiency and energy management. Through sensor-equipped pumps and monitoring devices, Automatic Pump Control continuously collects comprehensive data on flow rates, pressure levels, energy consumption, and equipment performance. This real-time data provides valuable insights into pump operation patterns, identifying inefficiencies and opportunities for optimization.

By employing sophisticated data analytics and visualization tools, businesses can gain a deep understanding of their pumping systems' behavior and energy usage trends. With this insight, operators can make informed decisions to fine-tune pumping schedules, optimize equipment settings, and address potential energy wastage. Real-time data collection empowers enterprises to proactively identify and rectify operational inefficiencies, ultimately contributing to reduced energy consumption and lower utility costs.

In conclusion, the adoption of Automatic Pump Control solutions presents a transformative opportunity for businesses to enhance energy efficiency and reduce operational expenses. By harnessing real-time data collection, remote monitoring, and automation, enterprises can gain profound insights into their pumping systems, implement proactive maintenance strategies, and optimize pump operations for energy savings. The synergy of these three aspects within Automatic Pump Control not only elevates operational performance but also significantly lowers energy consumption and associated costs.

-

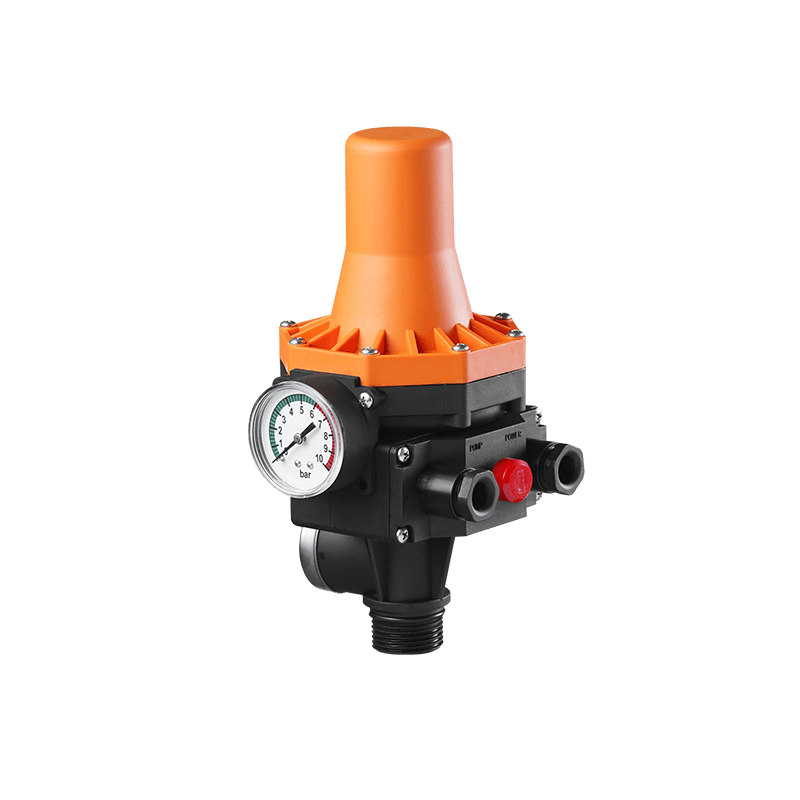

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español