Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Innovative Solutions in Booster Pump Automatic Switches and Cut-In/Out Pressure Switches

In the ever-evolving landscape of water supply systems, advancements in technology continue to revolutionize the efficiency and reliability of pump operations. Booster pump automatic switches and cut-in/cut-out pressure switches play pivotal roles in ensuring good performance and maintaining consistent water pressure levels. Let's delve into the latest developments in these critical components and their impact on the water supply industry.

Booster Pump Automatic Switches: Streamlining Water Distribution

Booster pump automatic switches are essential components in water distribution networks, particularly in areas where water pressure may be insufficient to meet demand. These switches facilitate the automatic activation and deactivation of booster pumps based on pressure variations, ensuring consistent water pressure for residential, commercial, and industrial applications.

Recent innovations in booster pump automatic switches focus on enhancing reliability, efficiency, and user-friendliness. Manufacturers are integrating advanced sensor technologies and microprocessor-based control systems to provide precise pressure monitoring and seamless pump control. These intelligent switches can detect subtle pressure changes and adjust pump operation accordingly, minimizing energy consumption and maximizing system performance.

Furthermore, modern booster pump automatic switches feature user-friendly interfaces and intuitive controls, making installation and configuration straightforward for operators. Remote monitoring and diagnostic capabilities enable real-time supervision of pump operations, facilitating proactive maintenance and minimizing downtime.

Cut-In/Cut-Out Pressure Switches: Optimizing Pump Performance

Cut-in/cut-out pressure switches are fundamental components in pump control systems, regulating pump activation and deactivation based on preset pressure thresholds. These switches are commonly used in various water supply applications, including wells, tanks, and irrigation systems, to maintain desired pressure levels and prevent pump overloading or dry running.

Recent advancements in cut-in/cut-out pressure switches focus on improving accuracy, durability, and versatility. Manufacturers are employing robust materials and innovative design features to enhance switch reliability and longevity, even in harsh operating conditions.

Moreover, advancements in electronic pressure sensing technology have led to the development of digital cut-in/cut-out pressure switches with enhanced precision and responsiveness. These digital switches offer customizable pressure settings and programmable parameters, allowing for greater flexibility and adaptability to diverse system requirements.

Industry Impact and Future Trends

The adoption of advanced booster pump automatic switches and cut-in/cut-out pressure switches is reshaping the water supply industry, driving improvements in efficiency, reliability, and sustainability. By optimizing pump performance and minimizing energy consumption, these innovative components contribute to cost savings, reduced environmental impact, and enhanced customer satisfaction.

Looking ahead, industry experts anticipate further advancements in smart technologies, connectivity, and data analytics to continue revolutionizing pump control systems. Integration with IoT platforms and cloud-based monitoring solutions will enable remote management, predictive maintenance, and optimization of water distribution networks on a large scale.

As the demand for efficient and reliable water supply systems grows, the role of booster pump automatic switches and cut-in/cut-out pressure switches will become increasingly crucial. By staying at the forefront of technological innovation and embracing sustainable practices, stakeholders in the water supply industry can address evolving challenges and meet the needs of communities worldwide.

These advancements mark a significant step forward in the quest for more efficient and sustainable water supply systems. As the industry continues to embrace innovation, stakeholders can expect enhanced reliability, reduced energy consumption, and improved operational efficiency in pump control systems.

-

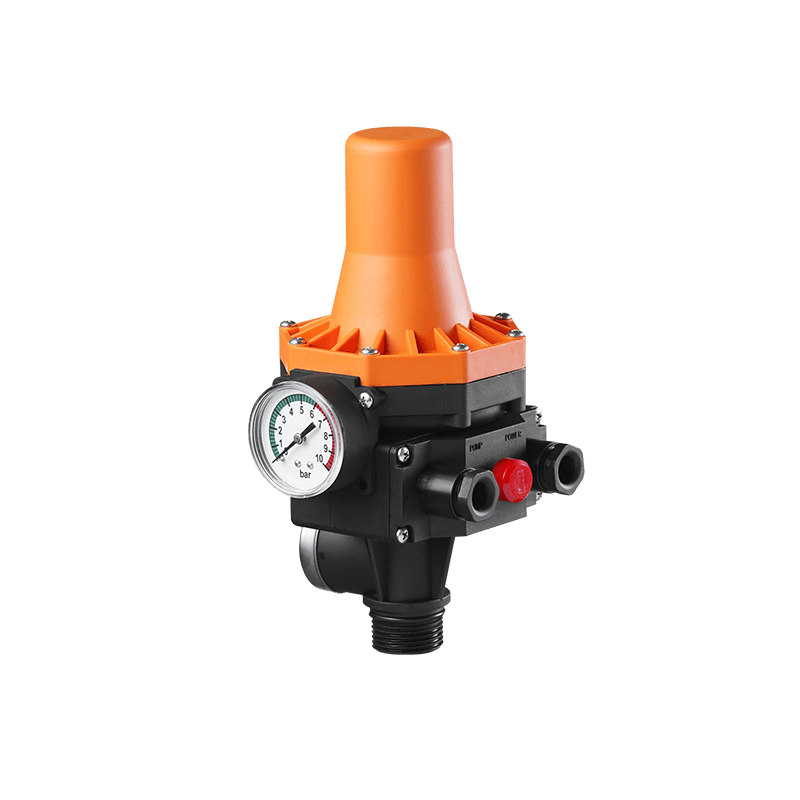

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español