Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Ensuring Quality in China Pressure Switch Manufacturing Comprehensive Approach

Wholesale Design OEM China Pressure Switch Manufacturer

The China Pressure Switch, a vital instrument in the realm of industrial automation and process control, is subject to stringent quality standards to ensure its reliability and longevity. The manufacturing process of these switches involves a series of meticulous steps aimed at delivering a product that meets high-quality benchmarks. This article examines the various measures taken to guarantee the quality of China Pressure Switches throughout their production lifecycle.

The journey towards a high-quality China Pressure Switch begins with the design phase. Engineers employ advanced computer-aided design (CAD) tools to create detailed blueprints that incorporate technological advancements and customer requirements. Simulations are run to predict the switch's performance under various conditions, allowing for the identification and rectification of potential issues before production begins.

The quality of raw materials used in the manufacturing of China Pressure Switches is a critical factor that influences the final product's performance. Manufacturers select materials that exhibit high durability, resistance to corrosion, and the ability to withstand bad temperatures and pressures. Rigorous testing and quality checks are conducted on incoming materials to ensure they meet the required specifications.

Manufacturing techniques are employed to fabricate China Pressure Switches with exceptional precision. Advanced machining centers, laser cutting machines, and automated assembly lines are utilized to maintain tight tolerances and ensure consistency across batches. The use of robotics and automated systems reduces human error and enhances the overall quality of the switches.

Continuous in-process quality control is an integral part of the China Pressure Switch production process. At various stages of manufacturing, the switches undergo rigorous testing to ensure they conform to the design specifications. This includes dimensional checks, material property tests, and functional tests to verify the switch's response to pressure changes.

Before leaving the factory, each China Pressure Switch is calibrated to ensure its accuracy and repeatability. Sophisticated test rigs simulate real-world operating conditions to evaluate the switch's performance. Tests for sensitivity, response time, and long-term stability are conducted to guarantee the switch's reliability in critical applications.

Adherence to international quality management systems, such as ISO 9001, is a testament to the commitment of China Pressure Switch manufacturers to quality. These systems provide a framework for continuous improvement, risk management, and the establishment of quality objectives and processes that are regularly audited and updated.

The workforce at China Pressure Switch manufacturing facilities is well-trained and skilled in production techniques and quality control methods. Regular training programs are conducted to keep the staff updated on new technologies, industry practices, and the importance of quality in every aspect of the production process.

Manufacturers of China Pressure Switches actively seek customer feedback to identify areas for improvement and to understand the specific needs of their clients. This feedback is instrumental in refining the product and enhancing its quality. Additionally, robust after-sales service and support ensure that any issues faced by customers are promptly addressed, further reinforcing the commitment to quality.

Investment in research and development is a key driver of quality in China's Pressure Switch manufacturing. Manufacturers are constantly exploring new materials, technologies, and methods to improve the performance, reliability, and efficiency of their switches. This drive for innovation ensures that the products remain at the forefront of the industry and meet the evolving demands of the market.

In conclusion, the quality of China Pressure Switches is a result of a comprehensive approach that encompasses design, materials selection, manufacturing processes, quality control, and after-sales service. By adhering to stringent standards and continuously striving for improvement, manufacturers ensure that these switches deliver the performance and reliability that customers expect and require.

-

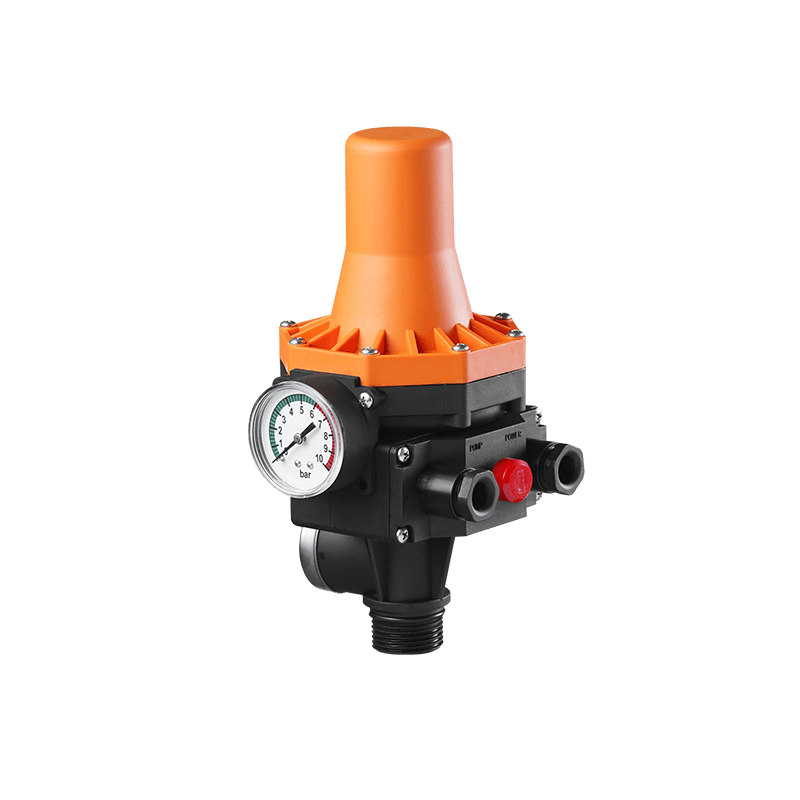

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español