Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

Assessing the Suitability of China Float Switches for Corrosive Liquid Detection

Custom Wholesale ODM China Pressure Float Switch Producer

In the field of industrial process control, the ability to accurately monitor and manage the levels of various liquids is essential for maintaining operational efficiency and safety. This is where the China Float Switch comes into play, a device that has been widely adopted for its reliability and precision in level detection. However, when it comes to the detection of corrosive liquids, the question arises: Are China Float Switches suitable for such demanding applications?

The China Float Switch, known for its durability and versatility, is designed to operate in a variety of environments. Its suitability for corrosive liquid detection depends on several factors, including the materials used in its construction, the design of the switch, and the specific chemicals it will be exposed to.

The materials used in the construction of a China Float Switch are critical in determining its corrosion resistance. Traditionally, float switches are made from materials such as plastic, stainless steel, and other alloys. For applications involving corrosive liquids, it is essential to select a China Float Switch that is made from materials that can withstand the chemical properties of the liquid in question. For instance, stainless steel variants of the China Float Switch are often chosen for their corrosion resistance, especially when dealing with acids, alkalis, and other aggressive chemicals.

Secondly, the design of the China Float Switch also plays a significant role in its suitability for corrosive liquid detection. Some switches are designed with a sealed chamber that houses the electronic components, protecting them from direct contact with the liquid. This design feature is particularly important when dealing with corrosive substances, as it prevents the liquid from causing damage to the internal components of the switch.

Moreover, the China Float Switch's operation mechanism must also be considered. The switch typically works by using a float that moves with the liquid level, activating a switch when the float reaches a certain point. In the case of corrosive liquids, the float and the mechanism that it operates must be resistant to the corrosive effects of the liquid. This often means that the float itself must be made from a material that is impervious to the liquid, and the mechanism must be designed to reduce wear and tear from the corrosive effects.

In addition to the material and design considerations, the China Float Switch's suitability for corrosive liquid detection also depends on the specific chemicals it will be exposed to. Different chemicals have different corrosive properties, and a switch that is suitable for one may not be suitable for another. Therefore, it is crucial to consult with the manufacturer or supplier of the China Float Switch to ensure that the switch is rated for the specific chemicals it will be used with.

Furthermore, the maintenance and lifespan of the China Float Switch in corrosive environments are also important considerations. Regular inspection and maintenance may be required to ensure that the switch continues to function correctly and to replace any components that have been compromised by the corrosive liquid.

In conclusion, the suitability of a China Float Switch for corrosive liquid detection is not a one-size-fits-all answer. It depends on the specific materials used in the switch's construction, the design of the switch, and the particular chemicals it will be exposed to. By carefully considering these factors and consulting with experts, it is possible to select a China Float Switch that is well-suited for the demanding task of detecting levels in corrosive liquids, ensuring the safety and efficiency of industrial processes.

-

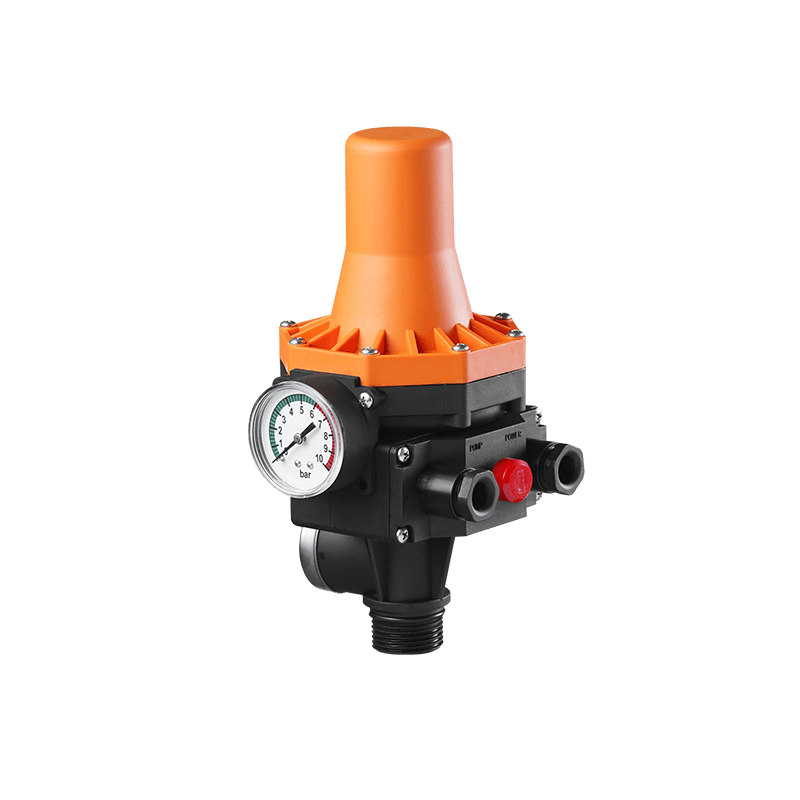

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español