Don't hesitate to send a message

Web Menu

Product Search

Exit Menu

A Comprehensive Guide of Calibrating an Automatic Water Pressure Switch

Automatic water pressure switches are essential components in water supply systems, ensuring good water pressure levels for various applications. However, to maintain accuracy and reliability, these switches require periodic calibration. Proper calibration ensures that the switch responds accurately to pressure changes, thereby preventing over-pressurization or insufficient pressure in water systems.

Understanding Automatic Water Pressure Switches:

Functionality:

Automatic water pressure switches monitor water pressure levels and control the operation of water pumps or valves to maintain desired pressure settings. These switches typically consist of a diaphragm, pressure sensing mechanism, and electrical contacts that activate when pressure reaches preset thresholds.

Importance of Calibration:

Calibration is essential to ensure that the automatic water pressure switch accurately detects pressure changes and operates within specified parameters. Over time, factors such as wear and tear, environmental conditions, and system changes can affect the switch's performance, necessitating calibration to maintain accuracy and reliability.

Steps to Calibrate an Automatic Water Pressure Switch:

Gather Necessary Tools:

Before starting the calibration process, gather the following tools:

Pressure gauge

Screwdriver (for adjusting switch settings)

Multimeter (for electrical testing)

Safety goggles and gloves

Disconnect Power:

To ensure safety during calibration, disconnect power to the water pump or system controlled by the pressure switch. This prevents accidental activation of the pump during calibration.

Access Pressure Switch:

Locate the automatic water pressure switch within the water system. Depending on the installation, it may be housed in a control panel, junction box, or directly mounted on the pump or pipeline.

Perform Initial Testing:

Using a pressure gauge, measure the current water pressure in the system. Compare this reading to the desired pressure settings specified for the application.

Adjust Pressure Settings:

Using a screwdriver, adjust the pressure settings on the automatic water pressure switch as needed to match the desired pressure levels. Refer to the manufacturer's instructions for guidance on adjusting pressure settings.

Test Switch Operation:

After adjusting the pressure settings, reconnect power to the water system and observe the operation of the pressure switch. Ensure that the switch activates or deactivates the pump or valve correctly in response to pressure changes.

Electrical Testing (Optional):

Using a multimeter, perform electrical testing on the pressure switch to verify proper functionality of the electrical contacts. Check for continuity and proper voltage readings according to the manufacturer's specifications.

Fine-Tuning (If Necessary):

If the switch does not operate within the desired parameters after initial calibration, fine-tune the pressure settings as needed and repeat the testing process until satisfactory results are achieved.

Considerations for Calibration:

Frequency:

Calibration frequency depends on factors such as usage, environmental conditions, and manufacturer recommendations. Typically, it is advisable to calibrate automatic water pressure switches annually or whenever there are significant changes in system conditions.

Accuracy:

Ensure that the pressure gauge used for calibration is calibrated itself to guarantee accurate pressure readings during the calibration process.

In conclusion, proper calibration of automatic water pressure switches is essential for maintaining accurate and reliable operation in water supply systems. By following the steps outlined in this guide and considering the necessary tools and precautions, operators can ensure that their automatic water pressure switches function goodly, preventing issues such as over-pressurization or insufficient pressure. Regular calibration helps prolong the lifespan of the switches and ensures the efficient operation of water supply systems, contributing to overall system reliability and performance.

-

EPC-1

EPC-1Monro EPC-1 model pump controller is the classic and basic type, was loved by user in the global mar...

-

EPC-3

EPC-3Monro EPC-3 spain design auto on and off press control, an intelligent and economical system designe...

-

EPC-5

EPC-5Monro EPC-5 model automatic pump control, a device which assembled on the water pump (recommended si...

-

EPC-9

EPC-9Monro EPC-9 model pressure controller, is a big power device for automatic control and protection of...

-

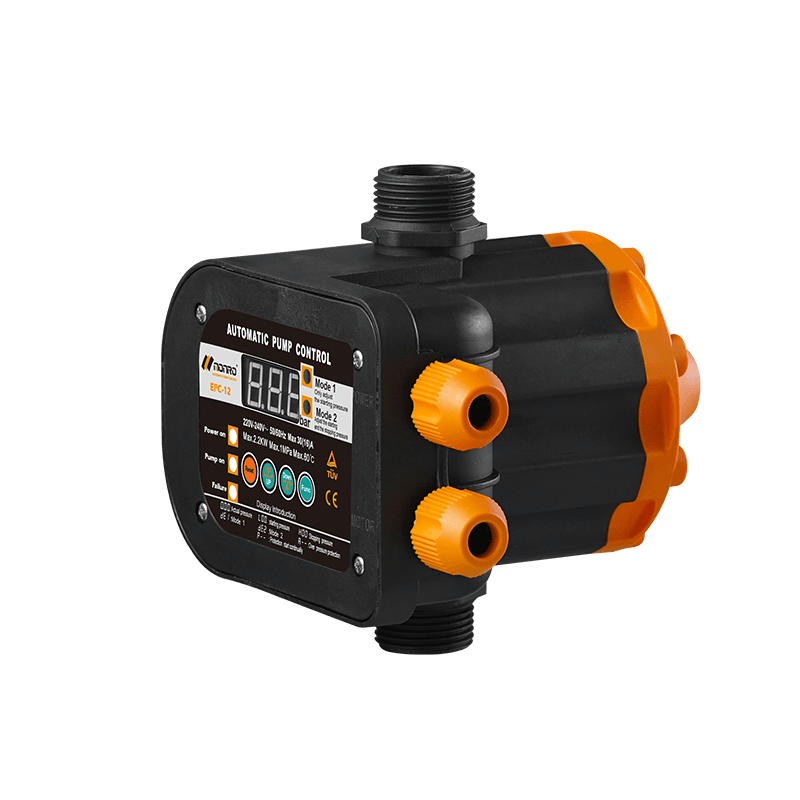

EPC-12

EPC-12Monro EPC-12 smart top-level automatic pump control is a multi-function model combined with traditio...

-

EPC-14

EPC-14Monro EPC-14 model pressure control is a big power device for automatic control and protection of el...

-

EPC-15

EPC-15Monro EPC-15 model automatic pump control, a device which assembled on the water pump (recommended s...

-

EPC-16

EPC-16EPC-16 is the new patent pump controller by Monro. Its key highlight is tooless (manual knob) start...

find our office

Committed to providing professional pressure control solutions for various types of water pumps and air compressors.

简体中文

简体中文 English

English Español

Español